In the ever-evolving landscape of modern manufacturing, the advantages of stacked molds have emerged as a pivotal innovation, driving quality upgrades and enhancing production efficiency in the “China Manufacturing, Quality Upgrade, Selling Globally” initiative. According to a recent report by MarketsandMarkets, the global injection molded plastics market is projected to reach USD 407.8 billion by 2025, emphasizing the growing importance of efficient mold designs in meeting increasing consumer demands.

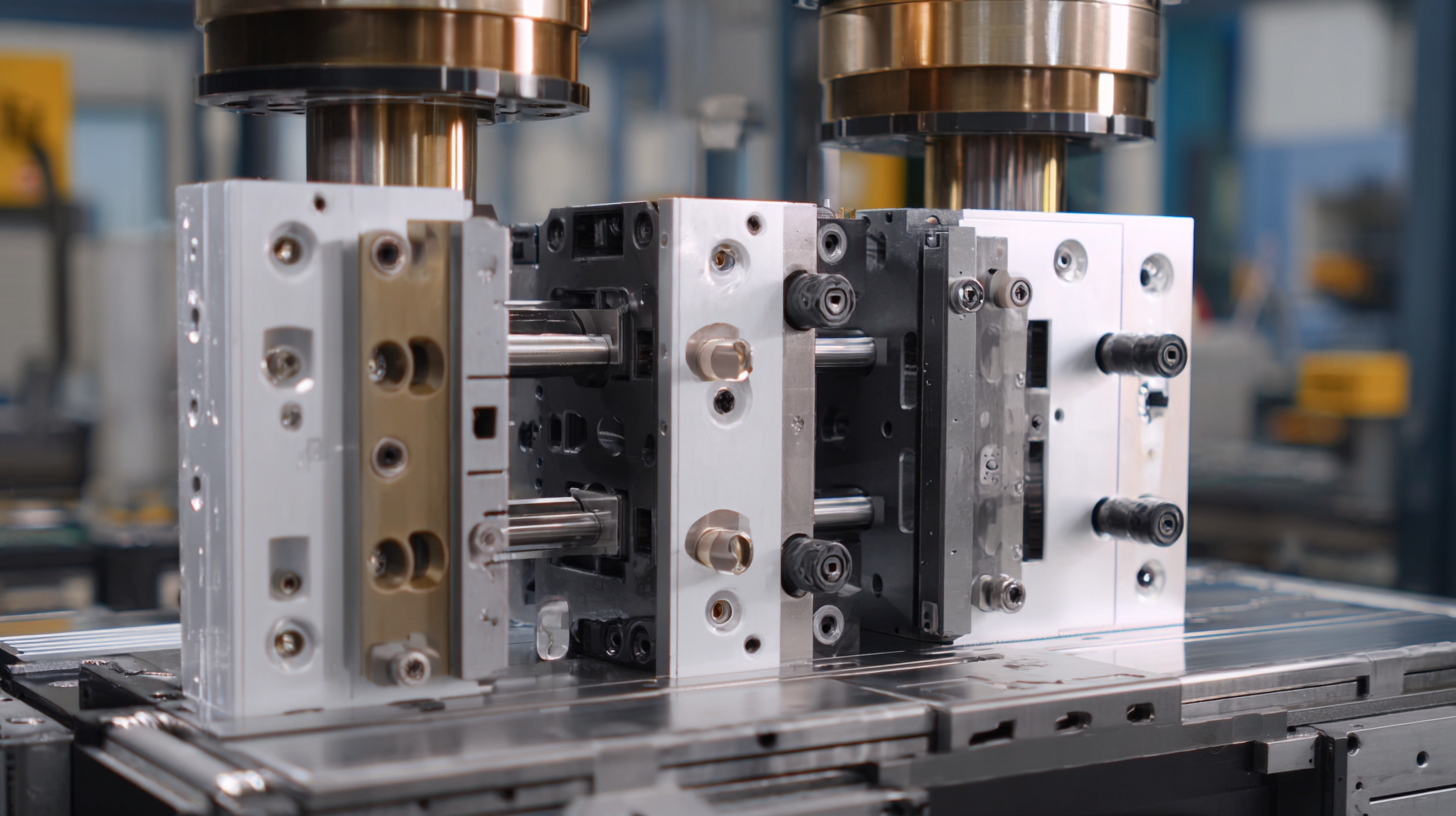

Stacked molds, which facilitate multiple parts being produced simultaneously, not only optimize resource utilization but also significantly reduce cycle times and manufacturing costs. This shift towards high-quality, cost-effective production aligns with China's strategic goals, allowing manufacturers to compete more vigorously on the global stage while ensuring superior product quality.

As we delve deeper into the unique benefits of stacked molds, it becomes clear that their implementation could be a game-changer for manufacturers aspiring to achieve excellence and sustainability in the global market.

Stacked molds are rapidly becoming integral to modern manufacturing, primarily due to their ability to revolutionize production efficiency. According to a recent report by MarketsandMarkets, the global mold market is projected to reach $4.9 billion by 2025, with innovations like stacked molds driving significant growth. These molds allow multiple parts to be produced simultaneously, effectively reducing cycle times and cutting material costs. By optimizing the use of space and resources, manufacturers can achieve higher output rates while maintaining quality standards.

Incorporating stacked molds can lead to an estimated 30-50% increase in production efficiency, as indicated by the American Mold Builders Association (AMBA). This efficiency stems from the reduced number of setups required and the ability to produce complex components without the need for additional tooling. Furthermore, these molds often enhance energy efficiency, driving down operational costs and making production more sustainable. As the competitive landscape continues to solidify, adopting stacked molds is becoming essential for manufacturers aiming to keep pace with industry demands while maximizing their return on investment.

Stacked molds are transforming high-volume manufacturing by enhancing

cost-effectiveness and improving return on investment (ROI). According to a recent report by the

Plastics Industry Association, the adoption of stacked mold technology can lead to a

reduction in production costs by up to 30%. This efficiency is achieved by allowing

manufacturers to produce multiple parts simultaneously, thereby maximizing the use of equipment and reducing cycle times.

The benefits are particularly pronounced in industries like automotive and

consumer goods, where large volumes and speed to market are critical.

Stacked molds are transforming high-volume manufacturing by enhancing

cost-effectiveness and improving return on investment (ROI). According to a recent report by the

Plastics Industry Association, the adoption of stacked mold technology can lead to a

reduction in production costs by up to 30%. This efficiency is achieved by allowing

manufacturers to produce multiple parts simultaneously, thereby maximizing the use of equipment and reducing cycle times.

The benefits are particularly pronounced in industries like automotive and

consumer goods, where large volumes and speed to market are critical.

Moreover, a study published by Injection Molding Magazine highlights that utilizing

stacked molds can significantly decrease the required investment in machinery. This is especially beneficial for

small to medium-sized enterprises (SMEs) that may struggle with the high costs of

traditional single-cavity molds. By leveraging stacked molds, these companies can achieve comparable efficiencies to larger

players without the proportional capital outlay. Consequently, stacked molds not only enhance production capabilities but

also drive profitability, making them an attractive option for manufacturers aiming to thrive in a competitive landscape.

In modern manufacturing, the quest for excellence often leads to the adoption of innovations that streamline production processes. Stacked molds are emerging as a transformative solution, particularly when it comes to enhancing quality control. By utilizing multiple cavities in a single mold, manufacturers can produce several parts simultaneously, significantly reducing the variability associated with single-cavity molds. This consistency not only increases throughput but also decreases the likelihood of defects caused by human error or material inconsistencies.

Moreover, stacked molds contribute to waste reduction throughout the manufacturing process. With improved synchronization between production cycles, there is less idle time and a more efficient use of materials. This integration means that manufacturers can minimize scrap and rework, translating into substantial cost savings. Additionally, the precision that stacked molds offer ensures that parts are produced to exact specifications, further lowering the risk of defects.

As the manufacturing landscape continues to evolve, the adoption of stacked molds presents a compelling case for quality improvement and resource optimization.

In the rapidly evolving landscape of modern manufacturing, agility has become paramount to meet shifting market demands. Stacked molds offer a unique solution, enhancing production flexibility while minimizing downtime. According to the 2022 Manufacturing Trends Survey by Deloitte, 76% of manufacturers recognize the necessity of adapting to customer needs swiftly—a feat made easier with the implementation of stacked mold technology. This innovative approach allows for the simultaneous production of multiple parts in a single cycle, significantly increasing output without compromising quality.

Moreover, as industries lean toward lean manufacturing practices, stacked molds play a crucial role in reducing waste and optimizing resource utilization. A study by the American Society of Mechanical Engineers revealed that manufacturers utilizing stacked molds reported a 30% reduction in lead times and a 25% decrease in material costs compared to traditional molding systems. This efficiency not only enhances operational effectiveness but also contributes to a more sustainable manufacturing process, aligning with the industry's push towards eco-friendly practices. As companies face mounting pressure to remain competitive, the adaptability offered by stacked molds becomes increasingly invaluable in agile manufacturing systems.

| Benefit | Description | Market Impact | Flexibility Level |

|---|---|---|---|

| Increased Production Efficiency | Stacked molds allow multiple parts to be produced simultaneously, reducing cycle times. | Higher throughput leading to better response to market demand. | High |

| Cost Efficiency | Reduction in material waste and energy consumption during production. | Lower operational costs, improving overall profit margins. | Medium |

| Design Versatility | Ability to create complex shapes and varied designs within a single setup. | More product options available for customers, enhancing market competitiveness. | High |

| Rapid Prototyping | Quick adjustments and iterations on mold design facilitate faster prototyping. | Accelerates time to market for new products. | Very High |

| Environmental Sustainability | Efficient use of materials leads to less waste and a smaller carbon footprint. | Improves brand image and meets consumer demand for sustainable practices. | Medium |

The modern manufacturing landscape is increasingly focused on sustainability, and stacked molds are emerging as a key innovation in this regard. By allowing multiple parts to be produced simultaneously, stacked molds significantly improve efficiency and minimize waste. This multi-part production approach not only reduces energy consumption during the manufacturing process but also optimizes material usage. When manufacturers employ stacked molds, they can decrease the number of cycles needed to produce the same volume of products, ultimately leading to lower greenhouse gas emissions associated with production.

Furthermore, the adaptability of stacked molds supports the use of biodegradable and recycled materials, further aligning manufacturing practices with sustainability goals. These molds can accommodate various materials without the need for additional tooling, fostering a circular economy where waste is minimized, and resources are continually reused. As industries strive for greener alternatives, the integration of stacked molds represents a pivotal step towards reducing the environmental impact of manufacturing processes, making it a forward-thinking choice for businesses committed to sustainable practices.