In the rapidly evolving world of manufacturing, understanding industry production standards is crucial for optimizing the quality and efficiency of Electronic Mold development. According to a recent report by MarketsandMarkets, the global electronic mold market is projected to grow from USD 2.5 billion in 2023 to USD 4 billion by 2025, driven by advancements in technology and increasing demands across various sectors, including automotive and consumer electronics. As manufacturers strive to meet these rising demands, it is essential to adopt best practices and ensure compliance with the latest standards. This blog will delve into the critical trends shaping the future of Electronic Mold production in 2025, providing valuable insights for industry professionals seeking to enhance their operational strategies and maintain competitive advantage in this dynamic landscape.

Quality control is a pivotal aspect of electronic mold manufacturing, as it directly impacts product reliability and performance. In industries such as electronics, precision is crucial; even minor defects can lead to significant failures in the final products. Adopting robust quality control measures ensures that every mold meets stringent industry standards, thereby reducing the risk of errors during mass production. This relationship between quality and efficiency not only enhances the trustworthiness of manufacturers but also drives customer satisfaction.

Furthermore, the process of implementing quality control in electronic mold production involves meticulous monitoring at every stage—from design to final output. Manufacturers utilize advanced technologies and methodologies such as Six Sigma, statistical process control, and material inspections to uphold the highest quality standards. By fostering a culture of continuous improvement, companies can adapt to changing market demands and technological advancements, ultimately solidifying their position in the competitive landscape of electronic manufacturing.

This chart illustrates the importance of various quality control parameters in electronic mold manufacturing. The data highlights how different factors contribute to overall production quality and adherence to industry standards.

In the electronic mold sector, adherence to industry production standards is crucial for ensuring quality and efficiency. The International Organization for Standardization (ISO) provides benchmarks that shape best practices in mold manufacturing. For instance, ISO 9001:2015 emphasizes quality management systems, promoting continuous improvement and customer satisfaction. Companies that comply with this standard have reported a 20% increase in operational efficiency, underscoring the importance of structured processes in the production landscape.

Additionally, the American National Standards Institute (ANSI) outlines specific criteria for electronic molds, including dimensional accuracy and material integrity. According to a recent industry report from Grand View Research, the global electronic mold market is expected to reach $10.6 billion by 2025, largely driven by the demand for high-precision components in consumer electronics. Emphasizing precision manufacturing can lead to reduced production costs by approximately 15%, making adherence to ANSI standards not just a regulatory requirement but also a strategic business decision for manufacturers aiming to stay competitive in this fast-evolving market.

The evolution of technology has been a driving force in enhancing the quality of electronic molds, significantly impacting various industries, including the automotive sector. As the global automotive mold market is projected to grow from $41.32 billion in 2024 to $60.88 billion by 2033, at a compound annual growth rate of approximately 4.4%, it is imperative to understand how technological advancements are shaping production standards.

Innovations such as advanced materials, automation, and precision engineering are redefining mold-making processes, leading to improved durability and efficiency. For instance, the integration of smart technologies into production lines enables real-time monitoring and data collection, ensuring that molds meet rigorous quality standards. As manufacturers adopt these modern techniques, the consistency and reliability of electronic molds are vastly enhanced, positioning them as essential components in the highly competitive automotive market. The continuous development in this field not only boosts productivity but also opens up new possibilities for complex mold designs that were previously unfeasible.

| Dimension | Measurement Standard | Technological Advancements | Effect on Quality |

|---|---|---|---|

| Dimensional Accuracy | ±0.005 mm | CNC Machining | Increased precision and reduced tolerance |

| Surface Finish | Ra 0.8 μm | Laser Texturing | Enhanced conductivity and aesthetics |

| Material Properties | Tensile Strength: >500 MPa | 3D Printing with Advanced Alloys | Improved durability and thermal resistance |

| Production Efficiency | Cycle Time: <5 hours | Automated Workflow Systems | Faster turnaround and reduced costs |

| Quality Control | Defect Rate: <1% | Real-time Monitoring Systems | Higher reliability and customer satisfaction |

The global electronic mold manufacturing industry is subject to a variety of standards that can significantly impact product quality and consistency. According to a report from the International Organization for Standardization (ISO), adherence to ISO 9001 standards can enhance operational efficiency and customer satisfaction, with companies reporting a 20% increase in productivity when implementing structured quality management systems. In addition, compliance with IPC-2221 standards, which focus on the design of printed circuit boards and assemblies, is crucial for ensuring reliability in electronic mold applications.

A comparative analysis of these standards across different regions reveals notable discrepancies. For instance, manufacturers in North America often prioritize ISO compliance, while Asian manufacturers may lean more towards JIS (Japanese Industrial Standards) due to market demand and regional practices. Market research indicates that 65% of electronic mold producers in Asia are currently aligning their production processes with international standards like RoHS (Restriction of Hazardous Substances), reflecting a growing trend toward sustainable practices in response to global environmental regulations. This shift not only enhances product credibility but also opens up new markets for manufacturers striving to meet international benchmarks.

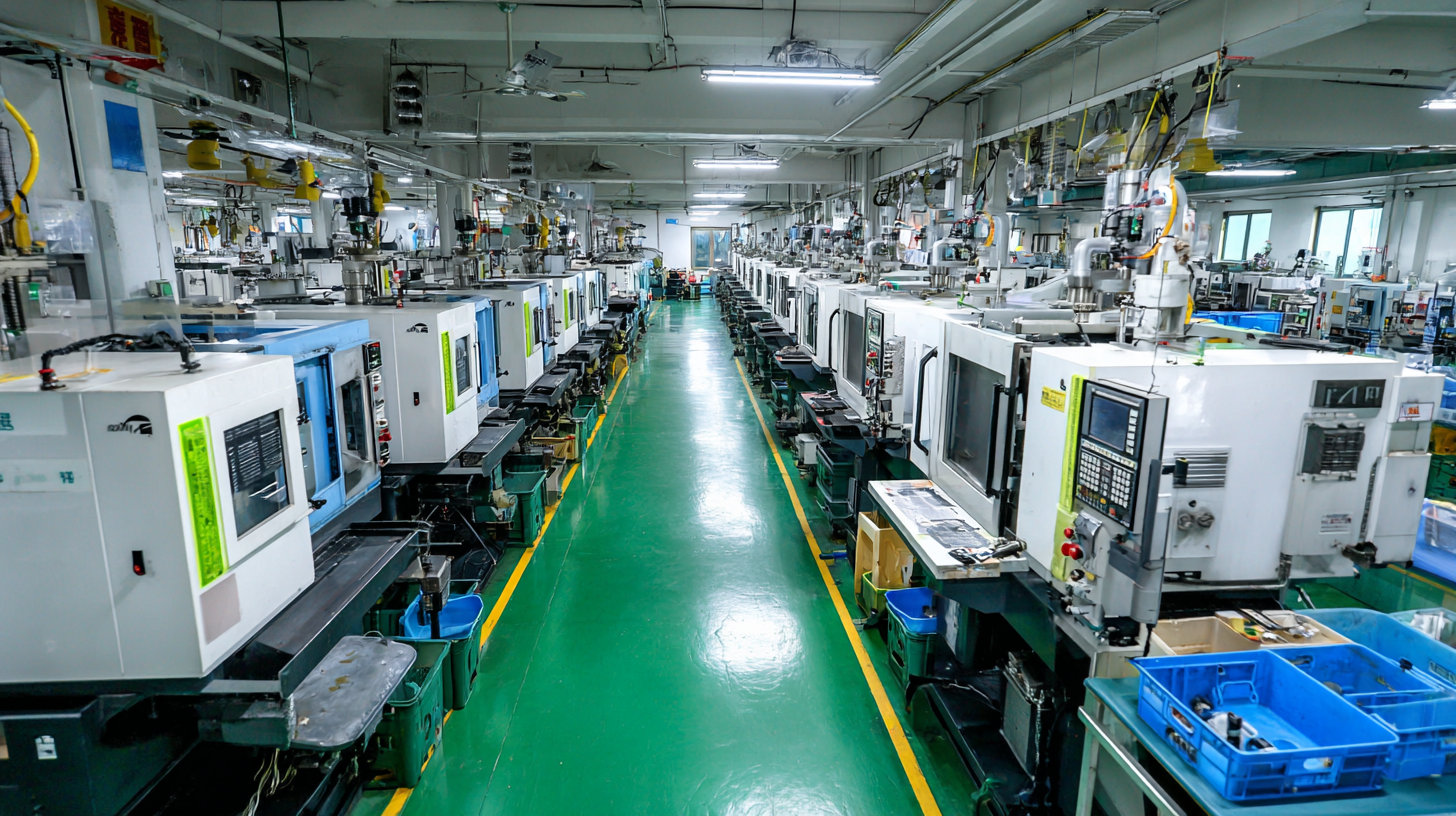

When selecting a high-quality electronic mold manufacturer in China, it is crucial to consider several best practices to ensure that the production process meets industry standards. First, evaluate the manufacturer’s experience and expertise in producing electronic molds. Look for companies with a proven track record and specialization in your specific type of mold. A manufacturer with significant experience can better understand the complexities of electronic components, including their durability and efficiency, yielding a better product that aligns with your requirements.

Another vital aspect is to assess the manufacturer’s certifications and compliance with international industry standards. Quality control measures, such as ISO certifications, indicate that a manufacturer adheres to strict production protocols and maintains high-quality assurance practices. In addition, visiting the production facility, if feasible, can provide insight into their operational processes, technological capabilities, and overall production environment. Engaging directly with the team can also facilitate better communication and understanding of your specific project needs, ensuring that both parties are aligned and capable of delivering a superior electronic mold.