As the aerospace industry continues to evolve, the design and production of aircraft components are entering a transformative era driven by technological innovations and emerging trends. The focus on efficiency, sustainability, and performance enhancement is reshaping the landscape of aircraft manufacturing, and at the core of these advancements lies the concept of "Aircraft Mold." These molds are critical in the fabrication of lightweight, high-strength components that meet stringent safety and performance standards.

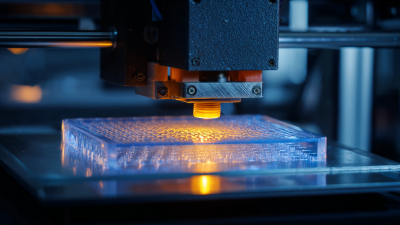

In 2025, we can anticipate a shift towards more advanced materials and automated manufacturing processes that will redefine traditional mold designs. Innovations in composite materials and 3D printing technologies are enabling manufacturers to create complex geometries and reduce waste, thereby improving overall productivity. Additionally, trends towards greater customization and the integration of smart technologies into the manufacturing process will offer new opportunities for enhancing mold designs.

This article will explore the top aircraft mold designs anticipated for 2025, highlighting the innovations shaping the future of aircraft component manufacturing. By staying informed on these trends, industry professionals can better prepare for the challenges and opportunities ahead in a rapidly changing aerospace landscape.

As we look toward 2025, the landscape of aircraft mold design is set to evolve dramatically, driven by technological advancements and a heightened focus on sustainability. One of the emerging trends is the integration of advanced composite materials that not only reduce weight but also enhance fuel efficiency. These materials are being designed with state-of-the-art mold technologies that allow for precision shaping and superior structural integrity. The use of computer-aided design (CAD) software is transforming the design process, enabling engineers to simulate various conditions and optimize mold geometry for better performance and reduced waste.

Additionally, there is a growing emphasis on automation and digitalization within the manufacturing process. The incorporation of additive manufacturing techniques, or 3D printing, is revolutionizing how molds are created. This innovation allows for rapid prototyping and the fabrication of complex designs that were previously unachievable, thus shortening production cycles and minimizing material usage.

Furthermore, machine learning algorithms are being deployed to predict and address potential issues in mold designs, leading to improved quality and consistency. These trends highlight a shift toward more efficient, sustainable practices in aircraft mold design, positioning the industry for a future where performance and environmental responsibility go hand in hand.

As the aerospace industry prepares for the advancements of 2025, several key innovations are shaping the future of aircraft mold designs. Driven by the demand for increased efficiency and performance, the use of advanced composite materials has surged. According to a recent report from the International Air Transport Association (IATA), the global aerospace composites market is projected to reach $34 billion by 2025, demonstrating a compound annual growth rate (CAGR) of over 8%. This increase in material sophistication requires mold designs that can accommodate complex geometries, ensuring optimal performance while minimizing weight.

Another significant trend is the adoption of additive manufacturing techniques in mold design. The use of 3D printing enables manufacturers to create intricate mold structures that were previously impossible with traditional methods. The 2022 report by the Aerospace Industries Association highlights that 27% of aerospace companies are now utilizing additive manufacturing to produce molds, leading to shortened production cycles and reduced material waste. These innovative technologies not only streamline the manufacturing process but also lead to more sustainable practices, aligning with the industry's broader goals of reducing carbon footprints and enhancing resource efficiency.

Integrating smart technologies into mold design further propels the aerospace sector into the future. Implementing sensors and IoT capabilities allows for real-time monitoring and data collection throughout the production phase. A study by the Aerospace Technology Institute indicated that manufacturers adopting smart mold technologies reported a 20% increase in production efficiency. This convergence of digital solutions and manufacturing processes heralds a new era in aircraft mold designs, ensuring they are not only innovative but also aligned with the industry's sustainability objectives.

The evolution of aircraft mold designs in 2025 is largely influenced by the integration of advanced materials that enhance efficiency and performance. As manufacturers seek to maximize weight reduction while maintaining structural integrity, materials such as carbon fiber composites and advanced thermoplastics are becoming the standard. These materials not only minimize the overall weight of the aircraft but also improve the mold's durability and lifecycle, leading to reduced maintenance costs and increased operational efficiency.

Tips for implementing these advanced materials include conducting thorough material assessments to understand their properties and compatibility with existing manufacturing processes. Additionally, collaboration with material scientists can provide insight into innovative practices that can optimize mold design. By staying informed about the latest advancements in materials technology, manufacturers can ensure their molds effectively meet the demands of next-generation aircraft.

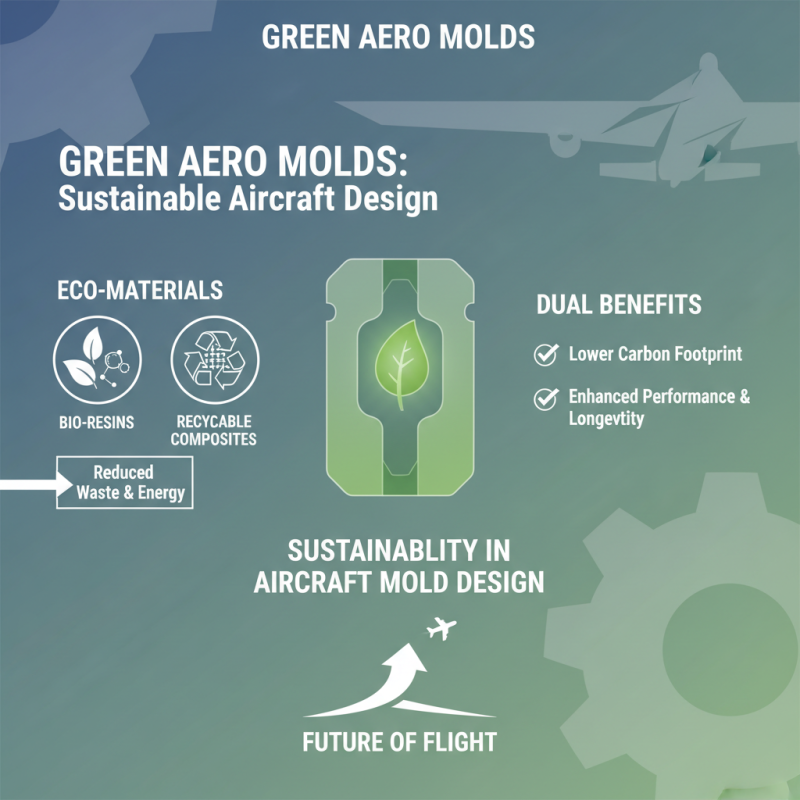

Embracing sustainable practices is another important trend in mold manufacturing. Utilizing eco-friendly materials and implementing energy-efficient processes not only align with industry regulations but also attract environmentally conscious clients. Companies should consider assessing their supply chains for sustainability, as this can enhance brand reputation while contributing to a greener aviation industry.

As the aircraft manufacturing industry moves towards a greener future, sustainability in aircraft mold design has become a top priority. Innovative practices are emerging that focus on reducing environmental impact throughout the mold creation process. By utilizing eco-friendly materials, such as bio-resins and recyclable composites, manufacturers can significantly decrease waste and energy consumption. These materials not only lower the carbon footprint associated with traditional mold manufacturing but also enhance the overall performance and longevity of the aircraft.

In addition to material innovations, advancements in technology are redefining mold design strategies. Techniques like additive manufacturing and 3D printing allow for more intricate and efficient mold shapes, minimizing material usage and production time. Moreover, the integration of computer-aided design (CAD) and computational fluid dynamics (CFD) enables designers to optimize molds for aerodynamics while ensuring a more streamlined production process. These innovations not only promote sustainability but also drive cost efficiency and performance enhancements, paving the way for a new era in aircraft manufacturing that prioritizes environmental responsibility without compromising quality.

The landscape of aircraft mold development is undergoing significant transformation in 2025, largely driven by new regulatory changes. As governments and aviation authorities implement stricter safety and environmental standards, manufacturers will need to adapt their mold designs to comply with these regulations. Innovations in materials, such as lighter and more durable composites, will be crucial as they not only meet regulatory demands but also enhance fuel efficiency and reduce emissions in aircraft. This shift may also lead to the adoption of advanced manufacturing technologies, including additive manufacturing and automation, which can streamline mold production processes while ensuring adherence to safety standards.

**Tips:** When considering aircraft mold designs, prioritize materials that are not only lightweight but also have enhanced thermal and fire-resistant properties. Staying informed about regulatory updates is essential, as it can influence design choices and manufacturing processes. Engage with industry experts and participate in discussions within aviation forums to anticipate upcoming trends and compliance requirements effectively.

Furthermore, as sustainability becomes a focal point in aviation, molds that incorporate eco-friendly practices in their production may hold a competitive advantage. Emphasizing recycling and waste reduction in mold manufacturing processes will not only satisfy regulatory requirements but also meet the growing consumer expectations for environmentally conscious practices in aviation. Collaborating with regulatory bodies early in the development process can provide valuable insights, ensuring that designs are both innovative and compliant.

| Mold Design Feature | Innovation Type | Impact on Production Efficiency | Regulatory Considerations |

|---|---|---|---|

| Lightweight Composite Materials | Material Innovation | Reduces fuel consumption and enhances performance | Compliance with weight regulations |

| Advanced Cooling Systems | System Design | Improves cycle times and reduces downtime | Adherence to thermal management regulations |

| Digital Twin Technology | Process Innovation | Optimizes maintenance schedules and reduces failures | Compliance with data security standards |

| 3D Printing for Molds | Manufacturing Innovation | Cuts production costs and lead times | Meets new additive manufacturing guidelines |

| Automated Inspection Systems | Quality Control Innovation | Enhances accuracy and reduces human error | Follows updated safety inspection regulations |