In the realm of vehicle production, efficiency is a paramount concern that significantly influences overall manufacturing timelines and costs. One critical aspect of achieving optimal production efficiency lies in the utilization of

Automotive Panel Molds.

These specialized molds are designed to create various exterior and interior panels of vehicles, ensuring precision and consistency in the production process.

Understanding the role of Automotive Panel Molds is essential for manufacturers aiming to streamline operations and enhance product quality. By employing

advanced technologies and materials in mold design, manufacturers can not only improve turnaround times but also reduce waste and enhance the durability of the vehicle components produced.

This article will explore the multifaceted contributions of Automotive Panel Molds to vehicle production efficiency, offering insights into best practices that can drive innovation and competitiveness in the automotive industry.

These specialized molds are designed to create various exterior and interior panels of vehicles, ensuring precision and consistency in the production process.

Understanding the role of Automotive Panel Molds is essential for manufacturers aiming to streamline operations and enhance product quality. By employing

advanced technologies and materials in mold design, manufacturers can not only improve turnaround times but also reduce waste and enhance the durability of the vehicle components produced.

This article will explore the multifaceted contributions of Automotive Panel Molds to vehicle production efficiency, offering insights into best practices that can drive innovation and competitiveness in the automotive industry.

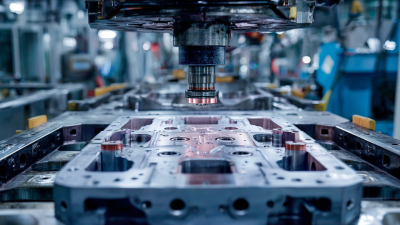

Automotive panel molds play a critical role in streamlining vehicle production processes, significantly enhancing efficiency and reducing costs. According to a recent study by the Society of Automotive Engineers (SAE), the precision and durability of molds contribute to a 20% reduction in production time for exterior components. This efficiency is largely due to the ability of advanced molds to produce complex parts with minimal waste, thereby lowering the overall material costs.

Moreover, the integration of computer-aided design (CAD) technologies in the mold-making process has revolutionized manufacturing workflows. A report from MarketsandMarkets indicates that companies adopting CAD for mold design have seen a 30% increase in project turnaround time. This technological advancement not only streamlines the design phase but also ensures higher quality standards, leading to fewer defects and rework in production lines. The strategic use of automotive panel molds thus emerges as a key driver in optimizing production efficiency and boosting competitiveness in the automotive sector.

The efficiency of panel mold design and manufacturing is critical in optimizing vehicle production. One of the primary factors influencing this efficiency is the precision of the mold design. Advanced CAD software allows engineers to create highly accurate models that reduce material waste and ensure a perfect fit for each vehicle component. Additionally, integrating simulation tools can help forecast potential issues, allowing designers to make adjustments before the physical production starts, thereby saving time and resources.

Another key factor is the choice of materials used in the mold construction. Using high-quality, durable materials can significantly extend the lifespan of the molds, reducing the frequency of replacements and maintenance. The cooling system design within the mold also plays a crucial role; efficient cooling can decrease cycle times, leading to faster production rates. Furthermore, adopting automation and advanced manufacturing techniques can streamline the mold manufacturing process, making it more consistent and less labor-intensive, which ultimately enhances overall production efficiency in the automotive industry.

The automotive industry is undergoing a transformative shift driven by innovative technologies that significantly enhance the functionality of automotive molds. Advances in materials science have led to the adoption of lightweight, durable composites, which improve the efficiency of production processes. According to a recent report by MarketsandMarkets, the automotive mold market is projected to reach $6.5 billion by 2025, growing at a CAGR of 5.8%. This growth is largely attributable to the increasing demand for high-performance molds that can withstand the rigors of advanced manufacturing techniques.

Furthermore, the integration of automation and precision engineering in mold production is revolutionizing workflow efficiency. Technologies such as additive manufacturing and CNC machining allow for rapid prototyping and reduced lead times, enabling manufacturers to respond quickly to market demands. A study by Deloitte indicates that automotive companies leveraging these technologies can enhance their production efficiency by up to 30%, thus significantly lowering operational costs. The emphasis on smart molding solutions not only streamlines processes but also contributes to the overall sustainability of vehicle production, aligning with industry-wide goals for reduced environmental impact.

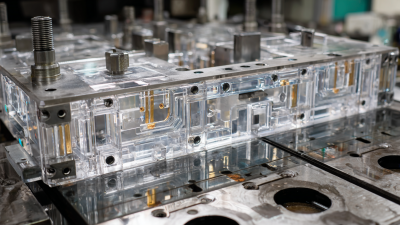

Proper maintenance and handling of automotive panel molds is crucial for ensuring vehicle production efficiency. Automotive molds, made from high-performance materials such as polypropylene, require regular checks to prevent wear and tear, which can lead to defects in the final product. Using sustainable and lightweight materials can also enhance the durability of molds while reducing environmental impact. Implementing best practices in mold maintenance can lead to reduced cycle times and improved output quality, factors that are essential in today’s competitive automotive landscape.

To handle these molds effectively, temperature control during storage and operation is vital. Extreme conditions can warp or damage molds, affecting their performance. It’s also important to use proper cleaning protocols to avoid contaminant buildup, which can compromise the molding process. Regular inspections and timely interventions not only extend the lifespan of molds but also play an integral role in maintaining production schedules, ultimately leading to higher efficiency and lower operational costs in vehicle manufacturing.

| Aspect | Details |

|---|---|

| Material Type | Aluminum, Steel, Composite Materials |

| Typical Use | Body Panels, Interior Components, Structural Parts |

| Production Efficiency Impact | Shortened Cycle Times, Reduced Scrap Rates |

| Maintenance Best Practices | Regular Cleaning, Inspection, Lubrication, and Storage |

| Handling Recommendations | Use of Proper Lifting Equipment, Avoiding Dropping or Impact |

| Common Issues | Wear and Tear, Corrosion, Alignment Issues |

| Expected Lifespan | 5-10 years depending on usage and maintenance |

The advancement of automotive panel molds plays a crucial role in enhancing vehicle production efficiency, particularly as innovative materials emerge to improve mold performance and production speed. With the shift toward lightweight composite structures, manufacturers are leveraging advanced materials not only to reduce vehicle weight but also to optimize the injection molding process. This technological evolution allows for the creation of complex geometries while maintaining structural integrity, thereby accelerating production timelines and reducing costs.

The introduction of breakthroughs such as MR-MUF's heat control technology exemplifies the impact of materials on mold efficiency. By significantly improving heat dissipation within the molding process, manufacturers can mitigate thermal stresses, preventing defects and ensuring better dimensional stability in final products. This innovation directly contributes to faster cycle times and enhanced product quality, pushing the boundaries of what is achievable in modern vehicle production. As companies continue to explore reactive processing techniques and additive manufacturing capabilities, the automotive industry stands to benefit from a synergy of advanced materials and cutting-edge processing technologies, ultimately driving production efficiency to new heights.