Advanced Mold Technology is reshaping the manufacturing landscape. By incorporating innovative techniques, manufacturers can enhance efficiency significantly. It is essential to understand how these technologies function in real-world applications.

Mold technology has evolved rapidly. Advanced techniques can reduce production time and improve product quality. For example, the integration of automation and smart sensors can streamline processes. However, many companies still struggle to adopt these solutions fully. They may face challenges like high initial costs or resistance to change within their teams.

Furthermore, not all advanced mold solutions fit every manufacturing scenario. Each operation has unique needs and limitations. Reflecting on these factors is crucial for finding the right technology. Manufacturers that embrace these advanced methods could gain a competitive edge but must stay agile and open to adaptation.

Advanced mold technology plays a pivotal role in enhancing manufacturing efficiency. By leveraging state-of-the-art designs and materials, manufacturers can significantly reduce production cycles. Reports suggest that adopting advanced mold technologies can lead to a 30% decrease in cycle time. This improvement not only speeds up the manufacturing process but also lowers operational costs.

A critical component is the use of simulation tools. These tools help in identifying potential design flaws early in the process. According to a survey, 55% of manufacturers reported that simulation has minimized costly alterations during production. However, challenges remain. Many companies still rely on outdated processes. Inadequate training on new software and methodologies can hinder progress. It’s essential to create a culture of continuous learning and adaptation within the workforce.

Furthermore, the integration of materials like lightweight composites is gaining traction. These materials can enhance product performance while reducing energy consumption. Yet, transitioning to these advanced materials may require upfront investment. This can be daunting for smaller firms that struggle with resource allocation. Balancing innovation with practicality remains a prevalent concern in the industry.

Manufacturing efficiency is significantly influenced by mold technology. A recent industry report highlighted that optimizing mold design can reduce cycle times by up to 30%. This leads to faster production rates and lower operational costs. Effective cooling systems within molds can also play a pivotal role. They ensure uniform temperature control, crucial for maintaining product quality and reducing waste.

However, many manufacturers overlook maintenance. Regular checks can prevent serious downtime. It's proven that a well-maintained mold can last three times longer than a neglected one. Data shows that improper maintenance can lead to a 15% increase in defective products. Simple actions like cleaning and inspection are often ignored.

Additionally, workforce training is vital. A skilled team can troubleshoot problems effectively. Statistics suggest that investing in training can improve productivity by 20%. Unfortunately, not all companies prioritize this. Ignoring employee development can stifle innovation and efficiency. Thus, focusing on these key factors can truly harness mold technology for better outcomes.

Mold design can significantly affect manufacturing efficiency. Innovative techniques bring fresh insights into this complex process. For example, 3D printing aids in creating prototypes quickly. This technology allows designers to test and refine molds faster than ever. Rapid prototyping shortens the feedback loop, enabling teams to make decisions swiftly.

Another technique involves optimizing mold cooling systems. Effective cooling reduces cycle times, enhancing overall output. Many still underestimate this aspect. Poorly designed cooling channels lead to uneven temperatures. This creates defects and wasted materials. Regular evaluation of cooling designs is crucial for efficiency.

Incorporating simulation software is also essential. It helps predict mold performance under different conditions. This can identify potential issues before production. Troubleshooting before actual manufacturing saves time and costs. However, not every design will work perfectly. Constant iteration and learning from failures drive improvement in mold technology.

| Technique | Description | Impact on Efficiency | Expected Outcomes |

|---|---|---|---|

| Rapid Prototyping | Utilizing 3D printing technology to create mold prototypes quickly. | Reduces design cycle time by up to 30%. | Faster market entry, reduced initial costs. |

| Computer-Aided Design (CAD) | Advanced software tools to design and simulate molds. | Improves accuracy and reduces errors in mold design. | Higher quality molds, lower rework rates. |

| High-Quality Materials | Using advanced materials like aluminum alloys for mold making. | Increases longevity and performance of molds. | Reduced material costs over time, fewer replacements. |

| Cooling System Optimization | Enhancing cooling channels for quicker cycle times. | Improves thermal management, reducing cycle time by 20%. | Increased production rates and energy efficiency. |

| Injection Molding Simulation | Simulating the injection process to predict potential failures. | Identifies issues before physical testing, saving time and costs. | Enhanced reliability and consistency of final products. |

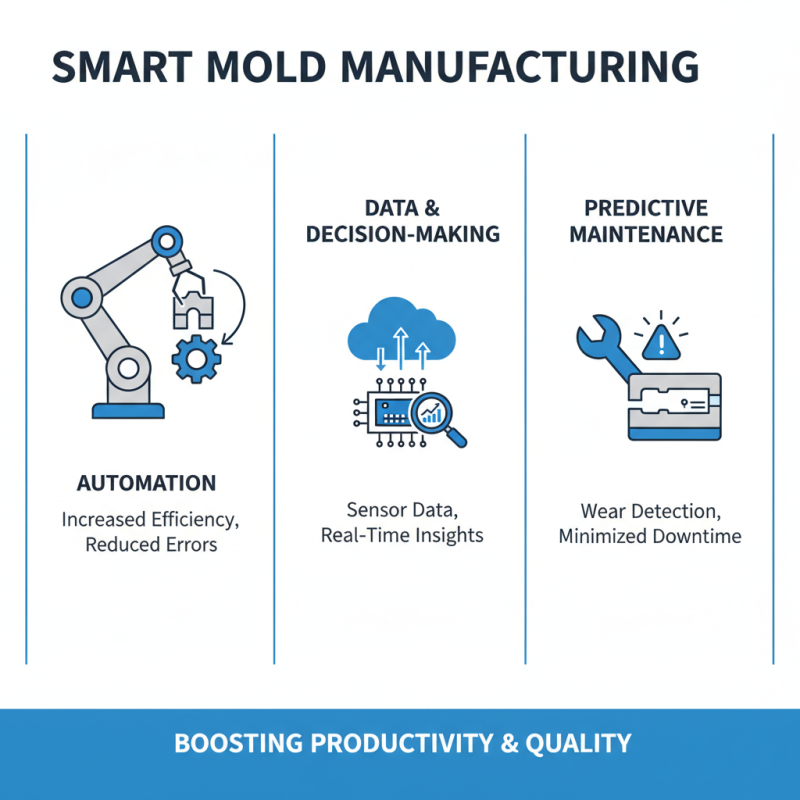

The integration of automation and smart technology in mold manufacturing has transformed production processes. Automated systems boost efficiency and reduce human error. Machines equipped with sensors gather data. This data helps in real-time decision-making. When a mold shows signs of wear, smart alerts trigger maintenance requests. This approach minimizes downtime and maximizes productivity.

However, adopting advanced technologies is not without challenges. Many manufacturers struggle with high initial costs. There is also a learning curve associated with new software systems. Ensuring all employees are trained can take time and resources. Some operators may resist changes, clinging to traditional methods. Addressing these issues requires open communication and strong leadership.

Moreover, the technology can lead to unexpected problems. Not every machine operates as expected after upgrades. Data overload can confuse decision-makers, leading to operational delays. Continuous assessment of the systems is vital. Companies must adapt and refine their processes, ensuring technology serves their unique needs. Embracing a flexible approach is crucial for success in this ever-evolving landscape.

Maintaining and optimizing mold equipment is essential for improving manufacturing efficiency. Effective upkeep not only boosts production speed but also enhances product quality. Regular inspections of molds often reveal minor issues before they escalate. Addressing wear and tear promptly is crucial. Check for alignment and support to avoid misalignments that can cause defects.

One significant aspect is the temperature control of mold equipment. Ensure that temperature sensors are calibrated correctly. Overheating can lead to material degradation. It's also wise to implement a regular cleaning schedule. Residue buildup can impact the mold's performance. Don’t underestimate the power of cleanliness.

Engaging operators in the maintenance process is vital. They can provide valuable feedback on mold performance. This input may highlight areas needing improvement. Sometimes, operators overlook small defects until they become bigger problems. Regular training can keep everyone aware of the latest best practices. Investing time in proper maintenance pays off in the long run.