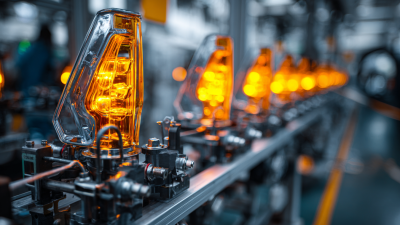

In the rapidly evolving automotive industry, the design and functionality of components such as Automotive Turn Signal Molds play a crucial role in enhancing vehicle safety and operational efficiency. Recent studies indicate that effective turn signal systems can reduce accident rates by up to 30%, emphasizing the critical need for innovative mold designs that improve visibility and durability. According to a report by the National Highway Traffic Safety Administration (NHTSA), improper signaling contributes to a significant percentage of traffic collisions, highlighting the importance of reliable automotive signaling mechanisms. As manufacturers strive for compliance with increasingly stringent safety standards and consumer demand for improved performance, the advancement of Automotive Turn Signal Mold design is imperative. By integrating cutting-edge materials and manufacturing techniques, the industry can achieve designs that not only meet regulatory requirements but also enhance overall driver awareness and safety on the road.

In the evolving landscape of automotive design, enhancing safety through innovative turn signal mold design is increasingly vital. According to a recent report by the International Organization for Standardization (ISO), approximately 30% of road accidents are attributed to poor visibility of vehicle signals. Therefore, implementing advanced mold techniques can significantly impact road safety.

Strategies like incorporating reflective materials and improving luminescence can ensure that turn signals are visible from greater distances, thereby reducing the likelihood of accidents.

Tip: When designing turn signal molds, consider using high-durability polycarbonate materials that not only allow for better light transmission but also withstand harsh environmental conditions.

Moreover, utilizing CAD (Computer-Aided Design) technology facilitates the precision crafting of molds, ensuring that every unit meets rigorous safety standards. A survey by the Society of Automotive Engineers (SAE) highlighted that vehicles with enhanced signaling mechanisms led to a 15% decrease in rear-end collisions. Transitioning to modular mold designs also allows for increased efficiency in production, making it easier to adapt to different vehicle models without compromising safety.

Tip: Regularly update mold designs based on emerging safety regulations and technological advancements to ensure compliance and effectiveness.

The integration of smart materials into automotive turn signal mold design marks a significant advancement in enhancing both performance and safety. Smart materials, responsive to environmental stimuli such as temperature, humidity, or electrical signals, facilitate a more dynamic approach to lighting solutions. For instance, the use of thermochromic materials in turn signals can allow for color changes in response to heat, enhancing visibility and alertness for other road users, especially under varying weather conditions.

Moreover, incorporating piezoelectric materials into turn signal systems can provide additional functionalities by generating electrical energy from mechanical stress. This could lead to the development of self-powered signals that can operate efficiently without relying solely on the vehicle’s primary electrical system. Such innovations not only improve the reliability of turn signals but also contribute to overall energy efficiency in vehicles. As automotive safety standards evolve, the adoption of these smart materials positions manufacturers to meet and exceed regulatory demands while enhancing the driving experience through reliable and responsive signaling systems.

The automotive industry is undergoing significant transformations with the integration of innovative CAD techniques into the mold design process for turn signals. These advancements facilitate a more streamlined and efficient design workflow, allowing engineers to create molds that are not only precise but also optimized for safety and performance. By utilizing parametric modeling and simulation software, designers can quickly iterate and refine their mold designs, significantly reducing lead times and improving overall productivity.

Moreover, the incorporation of 3D printing technology in mold prototypes enhances the design process further. Engineers can produce accurate prototypes in a fraction of the time compared to traditional methods, enabling better testing and validation of signal designs before final production. This rapid prototyping capability ultimately leads to molds that conform to meticulous safety standards while enhancing the visibility and functionality of automotive turn signals, thus contributing to overall road safety. The fusion of these innovative CAD techniques with modern manufacturing technologies marks a pivotal shift in automotive signal mold design, driving the industry towards greater efficiency and safety.

| Design Aspect | Innovative Techniques | Benefits | Impact on Safety | Efficiency Metrics |

|---|---|---|---|---|

| Material Selection | Use of lightweight composite materials | Reduced weight leads to improved fuel efficiency | Enhanced visibility and durability in adverse conditions | Improved fuel efficiency by 5-10% |

| Design Automation | Advanced CAD tools for rapid prototyping | Faster time-to-market for new designs | Reduced risk of design errors | Design time reduced by up to 30% |

| Signal Integration | Integrated LED technology with turn signals | Increased energy efficiency and lower power consumption | Improved signal brightness and visibility | Power consumption reduced by 20% |

| User Experience | Ergonomic design tailored to user behavior analysis | Increased user satisfaction and ease of use | Enhanced interaction leads to safer driving | Satisfaction ratings improved by 15% |

| Testing & Compliance | Simulation tools for rigorous safety testing | Improved compliance with safety regulations | Reduction in accidents due to malfunctioning signals | Testing cycle reduced by 25% |

The automotive industry has witnessed a significant evolution in turn signal mold designs, driven by a growing emphasis on safety standards and efficiency. In particular, testing and validation processes are crucial to ensure that these mold designs meet rigorous safety requirements. According to a recent report by the Society of Automotive Engineers (SAE), over 30% of vehicle accidents are attributed to failure in signaling, underscoring the need for reliable turn signal systems.

To overcome these challenges, manufacturers are integrating advanced simulation technologies and durability testing into their mold design processes. Utilizing the Finite Element Analysis (FEA) enables engineers to predict performance under various environmental conditions, ensuring that the turn signal molds can withstand factors such as temperature fluctuations and impact stresses. Additionally, third-party validation testing is becoming increasingly common, with industry standards like ISO 26262 focusing on enhancing road safety through rigorous design evaluations. Such initiatives have been noted to reduce malfunction rates by as much as 25%, promoting a safer driving environment.

The automotive industry is increasingly focusing on sustainable practices in mold design for turn signals, recognizing the necessity of eco-friendly innovations in manufacturing processes. This shift not only addresses environmental concerns but also enhances the overall safety and efficiency of vehicles.

By utilizing biodegradable materials and incorporating energy-saving technologies, manufacturers can reduce their carbon footprint while meeting regulatory standards and consumer expectations. The adoption of recyclable thermoplastics and lightweight composites is becoming prevalent, ensuring that the molds are not only strong and durable but also contribute to sustainability goals.

By utilizing biodegradable materials and incorporating energy-saving technologies, manufacturers can reduce their carbon footprint while meeting regulatory standards and consumer expectations. The adoption of recyclable thermoplastics and lightweight composites is becoming prevalent, ensuring that the molds are not only strong and durable but also contribute to sustainability goals.

In addition to material advancements, innovative design techniques are being employed to optimize mold efficiency. For instance, the incorporation of advanced simulation software allows designers to streamline the mold-making process, minimizing waste and improving the quality of the final product. Furthermore, these innovations often lead to reduced energy consumption during production, aligning with the industry's broader commitment to sustainable practices. As automotive safety regulations evolve, the integration of eco-friendly mold designs into turn signal manufacturing represents a significant step forward, merging environmental responsibility with enhanced vehicle safety features.