In today's rapidly evolving manufacturing landscape, the adoption of cutting-edge technologies is essential for staying competitive. Electronic Mold technology has emerged as a pivotal innovation in enhancing production line efficiency and flexibility. According to a report by Markets and Markets, the global electronic mold market is expected to grow from USD 2.4 billion in 2020 to USD 4.8 billion by 2025, reflecting a robust CAGR of 14.9%. This growth is driven by the increasing demand for precision and reduced production times in industries such as automotive, aerospace, and consumer electronics. By leveraging Electronic Mold technology, manufacturers can optimize their production processes, achieve higher accuracy, and reduce material waste, thereby not only enhancing profitability but also promoting sustainable practices. As we delve into innovative strategies to integrate Electronic Mold into your production line, we will explore the transformative impact it can have on your operational capabilities and market competitiveness.

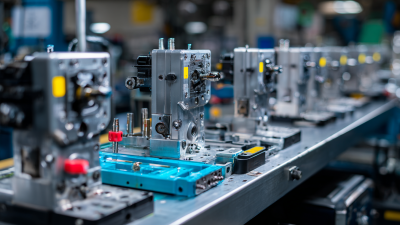

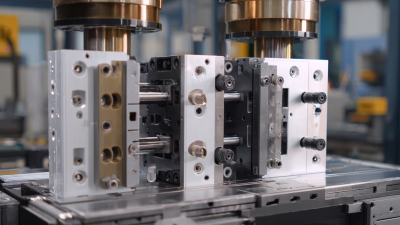

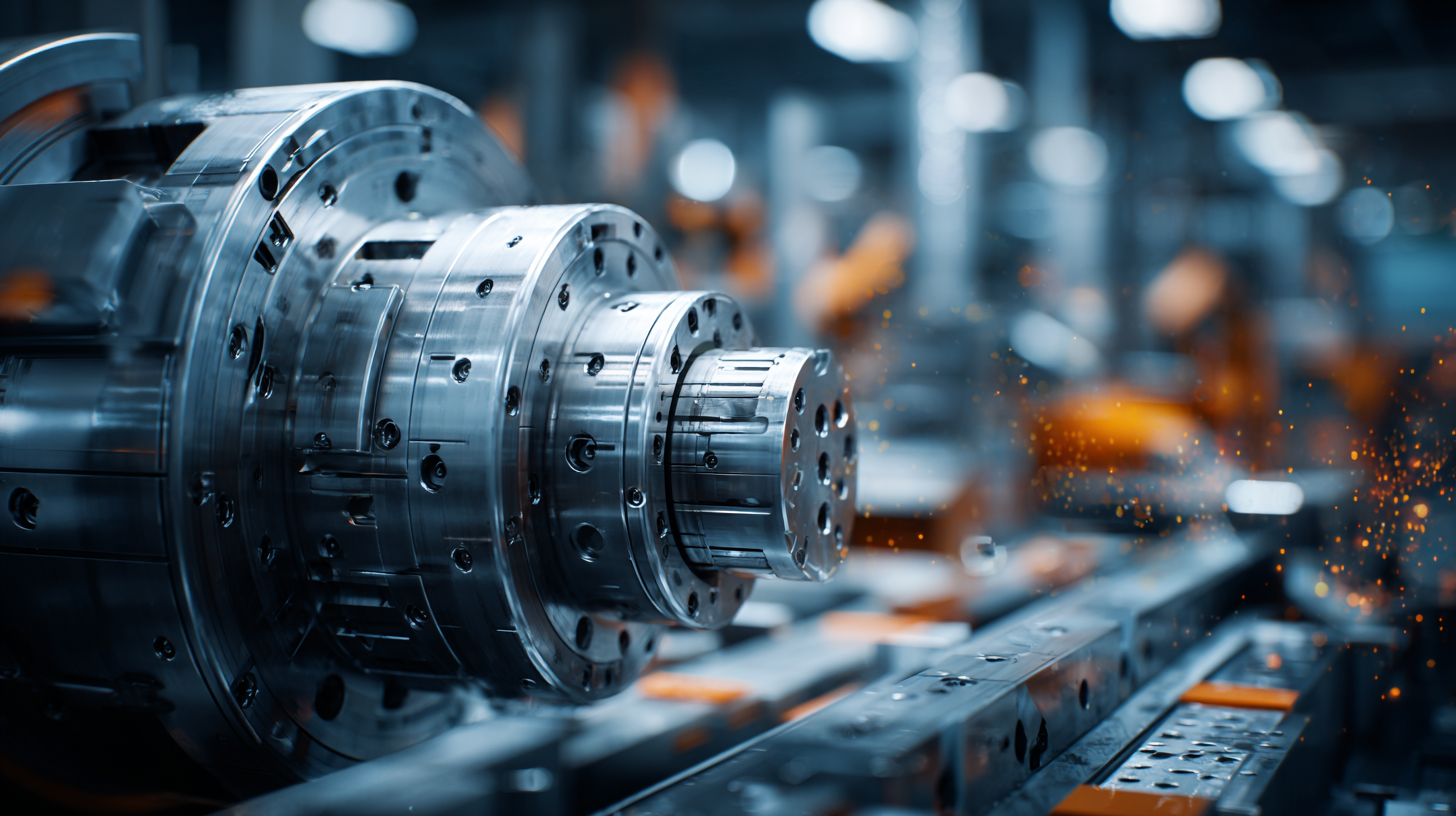

Electronic Mold Technology represents a significant advancement in manufacturing processes, transforming traditional production lines into high-efficiency systems. This innovative approach utilizes electronic components embedded in molds to enhance precision and flexibility during production. By integrating sensors and smart controls within molds, manufacturers can monitor and adjust parameters in real time, ensuring optimal performance and reducing waste. This shift not only improves product quality but also promotes more sustainable production practices.

The impact of Electronic Mold Technology on production is profound. It enables quicker adjustments to designs and specifications, allowing for greater customization of products. Manufacturers can also achieve higher throughput rates, as the technology streamlines operations and minimizes downtime. Additionally, the data collected through these smart molds provides valuable insights into production processes, facilitating continuous improvement and innovation. As industries increasingly embrace this technology, the potential for enhanced efficiency, reduced costs, and superior product quality is becoming a defining characteristic of modern manufacturing.

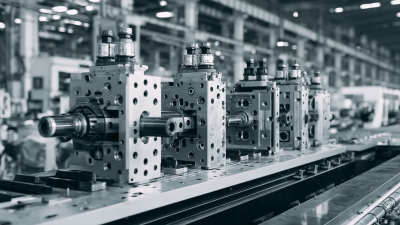

The adoption of electronic mold technology brings several key advantages that can significantly enhance production lines across various industries. According to a recent report from the International Society for Automation, companies implementing electronic molds have seen up to a 30% increase in production efficiency. This is largely due to the enhanced precision and control offered by electronic molds, which facilitate faster setup times and reduced waste during the manufacturing process.

Furthermore, electronic molds contribute to improved product quality and consistency. A study from the Society of Plastics Engineers highlighted that manufacturers using electronic mold techniques reported a 25% reduction in defects and variances in product dimensions. This consistency not only strengthens brand reliability but also leads to increased customer satisfaction and loyalty. By integrating electronic mold technology into production lines, companies can leverage these advantages to remain competitive in an increasingly demanding market.

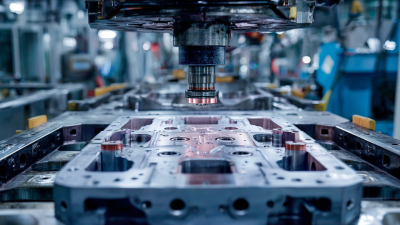

Integrating electronic molds into your existing production line can significantly enhance efficiency and precision. To successfully implement this innovative technology, start by assessing your current systems and identifying areas that could benefit from electronic molds. Conduct a thorough analysis of your production processes to determine the specific requirements for compatibility with these molds.

Tips: Consider collaborating with a technology partner who specializes in electronic molds to aid in the seamless integration process. This partnership can provide valuable insights and support, ensuring you meet the necessary technical specifications.

Once you’ve assessed your systems, gradually introduce electronic molds into your production line. Train your operators on the new technology to optimize usage and minimize disruptions. Incorporate feedback loops to continuously refine your processes based on real-time performance data.

Tips: Establish a dedicated team to oversee the transition. This team should focus on monitoring the performance of the electronic molds and making adjustments as needed, guaranteeing that your production line operates at its best.

This chart illustrates the improvement in production efficiency before and after integrating electronic mold technology into the production line. The implementation led to a significant increase in units produced per hour, highlighting the effectiveness of this innovative technology.

Training staff on electronic mold technology is crucial for optimizing production lines and staying competitive in the industry. As advancements in electronic mold technology continue to evolve, so too must the knowledge and skills of the workforce. Implementing structured training programs ensures that employees are well-equipped to leverage new technologies effectively.

Tips for Training Staff:

Incorporating these best practices into your training strategy can significantly enhance the proficiency of your team in using electronic mold technology, ultimately leading to increased productivity and innovation on the production line.

Investing in electronic mold technology can significantly enhance production line efficiency and product quality. One of the primary considerations when implementing this technology is the evaluation of its cost-effectiveness. While the initial investment may seem substantial, the reduction in production cycle times and improved accuracy can lead to considerable savings in the long run. Electronic molds allow for rapid adjustments and optimizations, minimizing material waste and downtime during production. By analyzing these factors, companies can create a financial model that highlights the potential return on investment.

Another crucial aspect is assessing the return on investment (ROI) from adopting electronic molds. Companies must consider both direct and indirect benefits, such as increased throughput, reduced labor costs, and enhanced product consistency. Collecting data on production output before and after the transition to electronic molds can provide valuable insights into performance improvements. Additionally, conducting a comprehensive cost-benefit analysis that includes the longevity and maintenance needs of electronic molds will allow businesses to make informed decisions that align with their strategic goals. By focusing on these evaluations, manufacturers can ensure that they are not only boosting innovation but also securing their financial future.