In the rapidly evolving landscape of manufacturing, the quest for high-quality electronic mold solutions has never been more critical. As the industry is expected to reach a market value of USD 12 billion by 2024, the demand for precision and reliability in electronic mold production is at an all-time high. According to a recent report by Markets and Markets, the electronic mold market is projected to grow at a CAGR of 8.5%, driven by advancements in technology and increased automation. This surge underscores the importance of selecting the right manufacturers who not only adhere to industry standards but also leverage innovative technologies to ensure superior quality and performance. Navigating the complexities of sourcing the best electronic mold solutions requires an understanding of these standards and a strategic approach to evaluating potential partners, ultimately leading to enhanced product quality and competitiveness in the market.

When sourcing electronic mold solutions, understanding key industry standards is essential for ensuring quality and performance. According to a report by MarketsandMarkets, the global injection molding market, which encompasses electronic mold solutions, is projected to reach USD 269.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 3.9%. This considerable growth underscores the necessity for manufacturers to adhere to specific metrics that influence product selection and compliance.

Key metrics for evaluating electronic mold solutions include precision, cycle time, and material compatibility. Precision, measured in micrometers, is critical in ensuring that molds produce parts that fit seamlessly with electronic components. A recent study highlighted that precision tolerances within ±0.01mm can drastically reduce assembly issues in electronic devices. Additionally, the cycle time, which averages around 15-30 seconds per part depending on complexity, directly impacts production efficiency and cost-effectiveness.

Furthermore, understanding material compatibility is vital, as not all plastics can withstand the thermal and mechanical stresses involved in electronic applications, as reported by the Society of Plastics Engineers. Prioritizing these metrics enables stakeholders to make informed decisions that align with industry best practices.

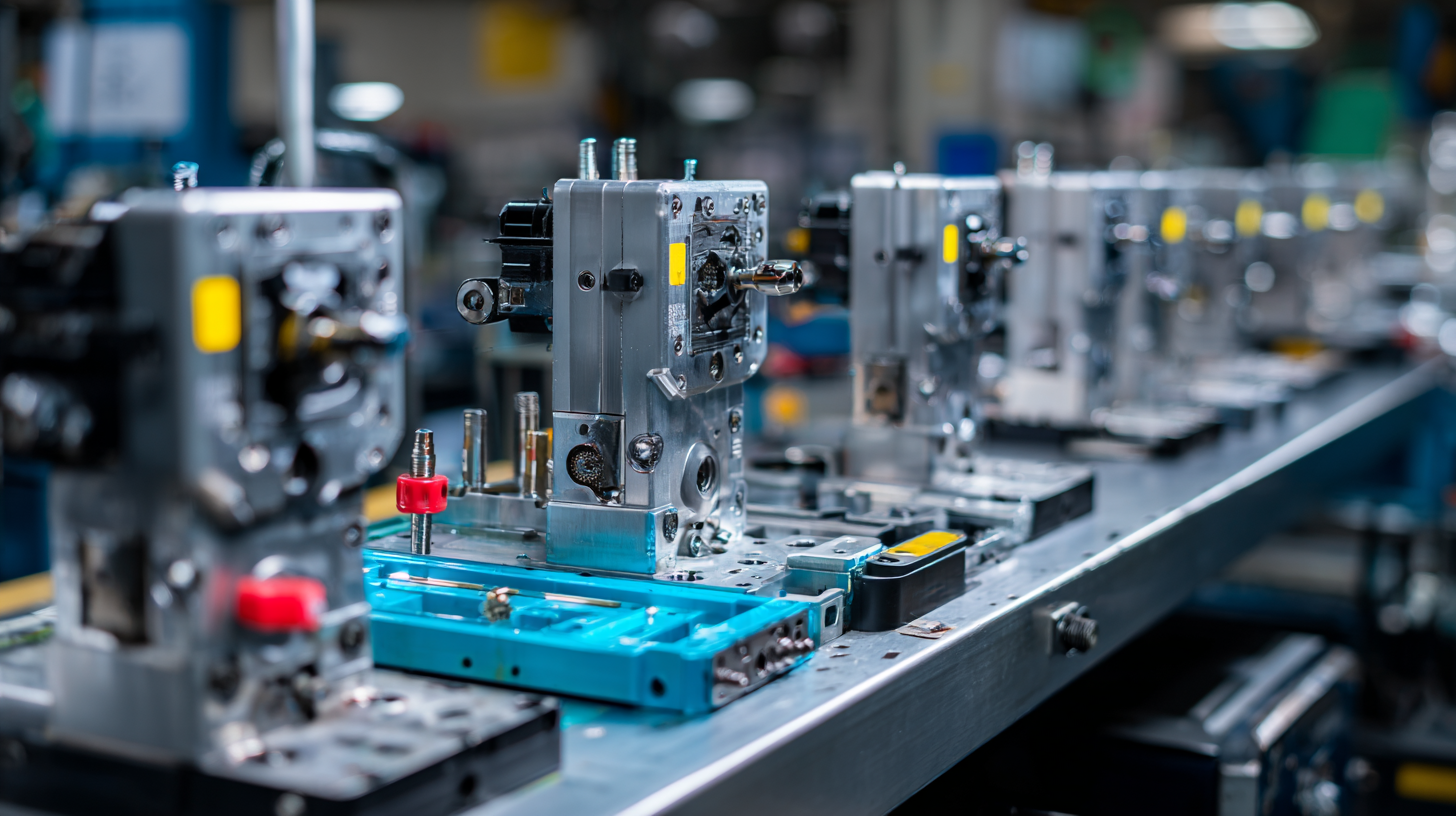

When sourcing electronic mold solutions, identifying qualified suppliers is paramount. The expertise in mold manufacturing can significantly impact the quality and efficiency of the production process. To evaluate potential suppliers, businesses should first assess their technical capabilities. This includes scrutinizing the materials used, the precision of their manufacturing processes, and their adherence to industry standards. A supplier well-versed in innovative technologies, such as CAD software and CNC machining, is likely to offer superior mold solutions tailored to specific project needs.

Additionally, reviewing a supplier's track record and client testimonials can provide valuable insights into their reliability and performance. It is essential to consider their experience with similar projects in your industry. Engaging with suppliers during preliminary discussions can also reveal their responsiveness and willingness to collaborate, which are critical factors in establishing a successful partnership. By focusing on these key aspects, businesses can ensure they choose capable suppliers who will contribute positively to their electronic mold projects.

When it comes to selecting materials for electronic molds, durability should be at the forefront of every decision. Various materials offer different mechanical properties, which directly influence the longevity and performance of the final product. For instance, thermoplastics are often favored for their excellent impact resistance and flexibility, making them suitable for applications requiring both strength and adaptability.

Conversely, thermosetting plastics provide enhanced heat resistance and dimensional stability, making them ideal for electronic environments subjected to high temperatures.

Another critical factor to consider is the environmental impact of material choices. Biodegradable options are gaining traction, especially in industries that prioritize sustainability. These materials, while providing adequate durability, allow manufacturers to meet eco-friendly objectives without compromising on the quality of the electronic components. However, it's essential to weigh the benefits against performance demands, as some eco-friendly options may not withstand rigorous operational conditions.

Ultimately, thorough comparisons of material properties and their suitability for specific applications will guide manufacturers in making the most informed choices for reliable electronic mold solutions.

In the rapidly evolving landscape of electronic mold production, innovative technologies play a pivotal role in enhancing efficiency and quality. One significant advancement is the integration of automation in the mold manufacturing process. Automated machinery and robotics streamline repetitive tasks, reducing human error and increasing production speed. By employing these technologies, manufacturers can achieve higher precision in mold design, which is crucial for the increasingly complex components used in modern electronics.

Furthermore, the implementation of advanced materials in electronic mold solutions has transformed the industry. High-performance polymers and composites not only improve durability but also reduce cycle times during production. These materials can better withstand the demands of electronic components, ensuring a reliable and efficient mold lifecycle. As manufacturers embrace these innovative approaches, they position themselves to meet the stringent requirements of industry standards while remaining competitive in the market. The synergy of automation and material advancements is clearly shaping the future of electronic mold solutions, leading to enhanced productivity and superior product quality.

When sourcing electronic molds, implementing best practices for quality assurance is crucial to ensuring that the final products meet industry standards. According to a recent report by the International Organization for Standardization (ISO), approximately 70% of defects in electronic components stem from issues in the molding process. This staggering statistic highlights the necessity for rigorous quality control measures at every stage of production. Using advanced inspection techniques, such as laser scanning and automated optical inspection (AOI), manufacturers can significantly reduce defects and improve the overall reliability of electronic molds.

Additionally, collaboration with suppliers who are certified in ISO 9001 can enhance the quality assurance process. A report from the American Society for Quality (ASQ) indicates that companies working with certified suppliers experience a 50% reduction in material waste and an increase in operational efficiency by up to 30%. Adopting high-quality material is equally important; research shows that utilizing thermoplastics known for their durability can enhance mold lifespan by 25%, thereby reducing costs associated with frequent replacements. By prioritizing these best practices, businesses can navigate industry standards more effectively and source electronic molds that consistently deliver exceptional performance.