As the automotive industry continually evolves, the demand for high-quality components becomes increasingly critical. According to a report by MarketsandMarkets, the global automotive lighting market is projected to reach USD 39.17 billion by 2026, growing at a CAGR of 8.6%. This surge underscores the importance of precision engineering in the production of key components like the Automotive Turn Signal Mold. These molds are integral to ensuring not only the functionality but also the safety and regulatory compliance of automotive lighting systems.

Furthermore, advancements in materials science and manufacturing processes have enabled the creation of more durable and efficient molds, which in turn enhances the overall reliability of turn signal systems. In this guide, we will navigate the essential factors and considerations for selecting the best Automotive Turn Signal Mold to meet your production needs in this competitive landscape.

When selecting the best automotive turn signal mold for your production needs, there are several key factors to consider that can significantly impact the quality and efficiency of your manufacturing process. First and foremost, material selection is crucial. Opt for molds made of high-quality materials that can withstand repeated use and provide excellent detail in the finished product. Steel molds, for instance, offer durability and longevity but may come at a higher upfront cost compared to aluminum molds.

Another essential consideration is the design of the mold itself. Ensure that it allows for optimal cooling and easy ejection of the turn signal components. Improper mold design can lead to defects and higher rejection rates in production.

**Tip:** Always check for the mold's compatibility with your existing machinery to avoid additional setup costs or modifications.

Furthermore, think about the supplier's reputation and support services. A reliable supplier will not only provide high-quality molds but also offer technical support and maintenance services to ensure minimal downtime during production.

**Tip:** Obtain samples or conduct trials before making a large purchase to validate the mold's performance in real production scenarios.

When it comes to manufacturing automotive turn signals, quality and precision in mold production are indispensable. A well-crafted mold ensures that each turn signal produced meets stringent safety and performance standards. Variations in mold quality can lead to defects, affecting not only the appearance but also the functionality and safety of the vehicle’s lighting systems. Thus, investing in high-quality molds is crucial for maintaining the integrity of your production line.

Tip: Always opt for molds made from durable materials such as steel or aluminum, as these can withstand high temperatures and pressures during the molding process, resulting in more consistent and reliable automotive parts.

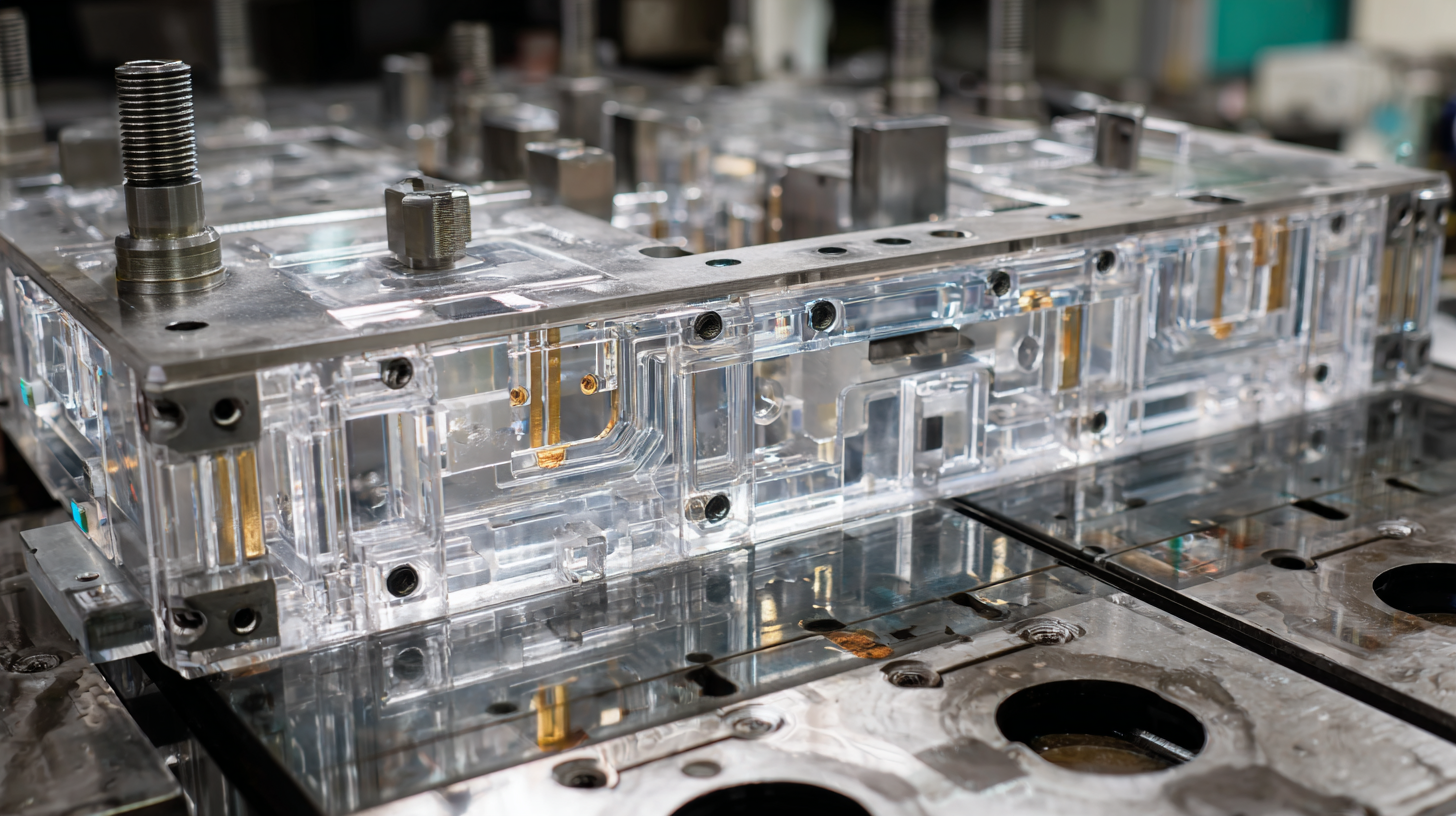

Furthermore, precision in mold design plays a significant role in the efficiency of the manufacturing process. Molds that are meticulously engineered can minimize material waste and reduce cycle times, leading to substantial cost savings. Ensuring that your mold design incorporates features such as proper ventilation and cooling channels not only enhances quality but also promotes faster production rates.

Tip: Collaborate with experienced mold manufacturers who utilize advanced technologies like CAD and CNC machining to achieve the highest level of accuracy, ensuring that your automotive turn signals are produced flawlessly every time.

When selecting the best automotive turn signal mold for production, understanding the material options available is crucial. The automotive industry is increasingly leaning towards lightweight materials, with a review indicating that advanced lightweight materials, such as high-strength steels and light alloys, can significantly enhance vehicle efficiency while maintaining safety standards. For instance, incorporating these materials can reduce vehicle weight by up to 20%, contributing to improved fuel economy and lower emissions, which are vital considerations in today's market.

Additionally, the advent of technologies like 3D printing is revolutionizing how automotive parts, including turn signals, are produced. This allows for greater customization of trim pieces and components, enabling manufacturers to respond more rapidly to consumer preferences while using materials that can be tailored for specific performance requirements. As the industry moves toward more sustainable practices, selecting molds made from eco-friendly materials will not only meet regulatory standards but also appeal to the environmentally conscious consumer. Understanding these material options is key to optimizing production efficiency and meeting evolving market demands.

| Material Type | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Polycarbonate (PC) | High impact resistance, good clarity | Can yellow over time, more expensive | Turn signal lenses, automotive lighting |

| Polypropylene (PP) | Lightweight, cost-effective, good chemical resistance | Lower clarified than polycarbonate | Housing components, back covers |

| Acrylic (PMMA) | Excellent light transmission, good UV resistance | Brittle compared to PC, scratching | Lenses and decorative components |

| Thermoplastic Elastomer (TPE) | Flexibility, excellent impact resistance | Higher costs, processing can be complex | Seals, flexible housing parts |

| Polyamide (Nylon) | Strong, durable, good heat resistance | Absorbs moisture, potential warping | High-stress applications, mechanical parts |

When selecting a manufacturer for automotive turn signal molds, evaluating

supplier capabilities is crucial for ensuring

quality and efficiency in production. Look for manufacturers with a

proven track record in the automotive

industry—data from the International Organization of Motor Vehicle Manufacturers

indicates that high-quality components can reduce warranty claims by up to

30%. Engaging with suppliers who have experience in

producing high-precision molds can significantly enhance the reliability of your product.

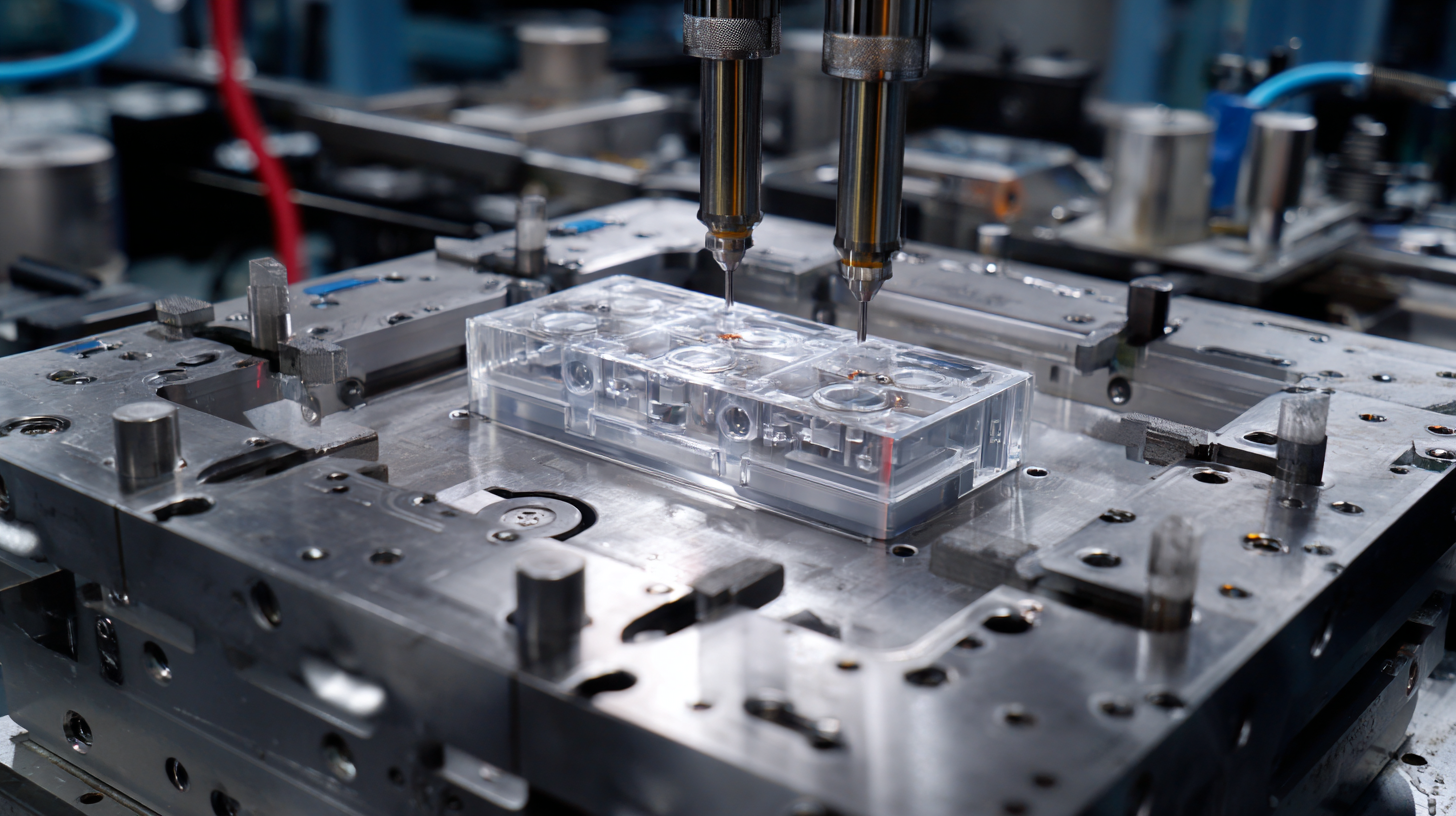

Tips: Consider the manufacturer's technological capabilities, including their

use of advanced manufacturing techniques

like injection molding and computer-aided design. These processes not only improve

product accuracy but also streamline production, which can lead to reduced lead times and costs.

Additionally, assess the supplier's quality assurance protocols. According to a

report from the Automotive Industry Action Group,

manufacturers implementing stringent quality control processes see a 25%

reduction in defect rates. Requesting details on certifications, such as

ISO/TS 16949, can provide peace of mind that the manufacturer adheres

to industry standards and practices. Remember, a capable supplier not only delivers on

quality but also becomes a strategic partner in your

production journey.

The design of automotive turn signals is increasingly influenced by global market trends that emphasize safety, efficiency, and aesthetic appeal. As the automotive industry evolves, manufacturers are responding to consumer demands for advanced safety features, leading to the integration of smarter turn signal designs. Innovations such as dynamic lighting and integrated LED technology not only enhance visibility but also contribute to a vehicle's modern aesthetic. These trends underscore the importance of selecting the right mold for production, as the precision and quality of the mold directly affect the final product's performance and appearance.

Additionally, environmental considerations are shaping the direction of turn signal design. With a growing emphasis on sustainability, manufacturers are exploring eco-friendly materials and production methods. The shift towards lightweight components that also comply with stringent regulatory standards requires a rethink of traditional manufacturing processes. As global regulations evolve, especially regarding emissions and safety, it becomes crucial for producers to stay ahead of these trends. By understanding the market's trajectory, companies can better align their production strategies, ensuring that the turn signals not only meet current standards but also anticipate future demands.