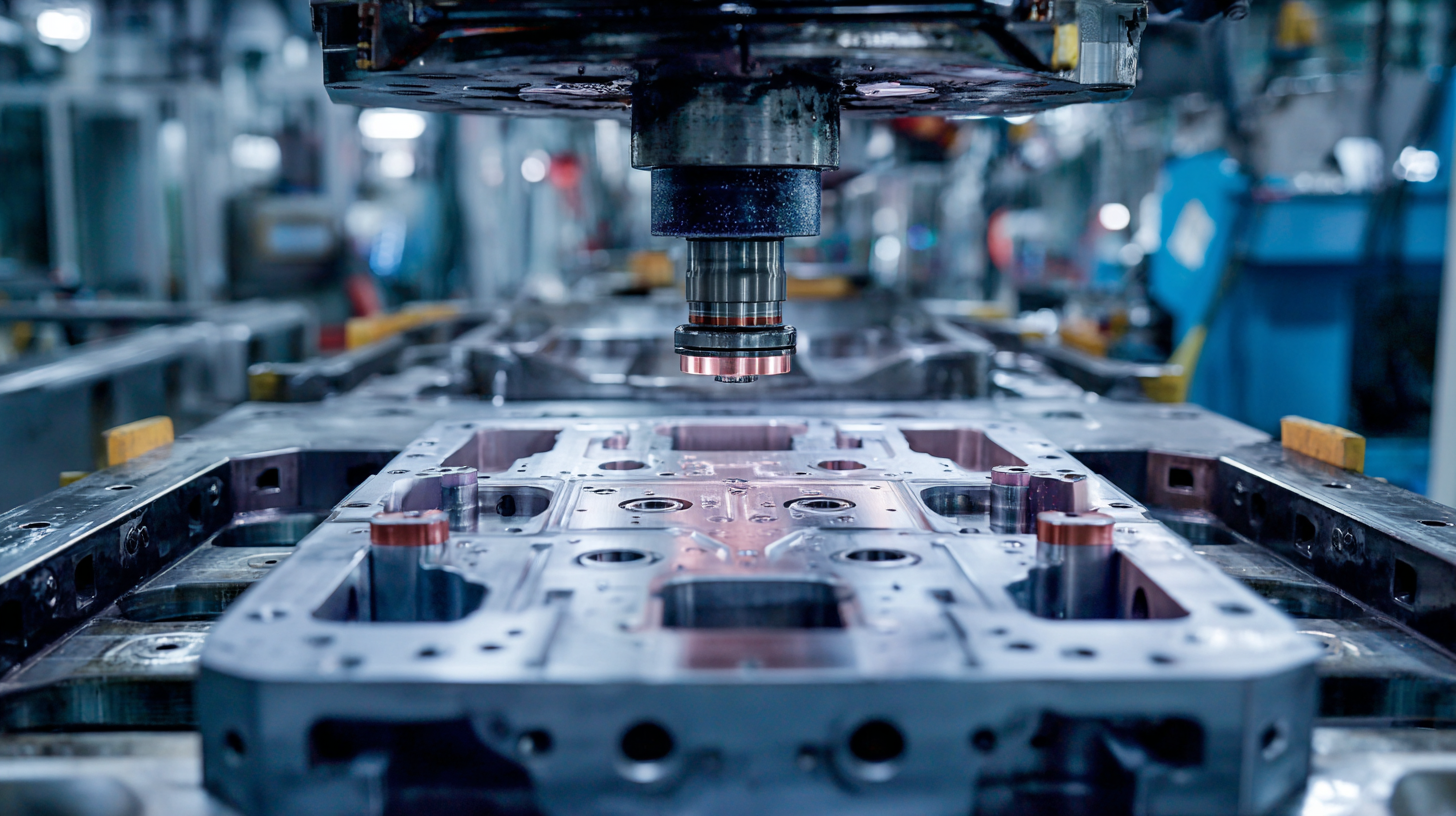

In the fiercely competitive global market, securing the best Automotive Mold is essential for manufacturers aiming to achieve excellence in design and production. However, navigating the complexities of export certification presents numerous challenges that can hinder progress and affect profitability.

Manufacturers must grapple with various regulatory hurdles, including compliance with international standards, documentation requirements, and quality assurance processes. These challenges not only create uncertainty in operations but also impact the overall marketability of Automotive Molds abroad.

Addressing these problems is crucial for businesses that aspire to expand their reach and enhance their reputation in the marketplace.

As we delve deeper into the intricacies of export certification, we will explore common issues faced by manufacturers and offer practical solutions to streamline the process, ensuring that their Automotive Molds meet the highest standards of quality and compliance.

In the fiercely competitive global market, securing the best Automotive Mold is essential for manufacturers aiming to achieve excellence in design and production. However, navigating the complexities of export certification presents numerous challenges that can hinder progress and affect profitability.

Manufacturers must grapple with various regulatory hurdles, including compliance with international standards, documentation requirements, and quality assurance processes. These challenges not only create uncertainty in operations but also impact the overall marketability of Automotive Molds abroad.

Addressing these problems is crucial for businesses that aspire to expand their reach and enhance their reputation in the marketplace.

As we delve deeper into the intricacies of export certification, we will explore common issues faced by manufacturers and offer practical solutions to streamline the process, ensuring that their Automotive Molds meet the highest standards of quality and compliance.

Export certification plays a crucial role in the automotive mold industry, ensuring compliance with international standards and enhancing market access. According to a report by Mordor Intelligence, the global automotive injection molding market is projected to reach USD 53.4 billion by 2026, growing at a CAGR of 5.2% during the forecast period. This growth emphasizes the significance of securing proper export certification, which helps manufacturers demonstrate their molds meet rigorous quality and safety requirements, thus facilitating smoother entry into diverse global markets.

Moreover, adherence to export certification helps companies mitigate risks associated with regulatory non-compliance. A study by Technavio highlights that companies investing in certification processes can enhance their competitive edge, as 62% of industry leaders indicate that certified products increase consumer trust and satisfaction. As automakers increasingly demand high-quality molds for their production lines, possessing the necessary export certifications amplifies manufacturers' reputations and opens doors to lucrative contracts worldwide. Ultimately, understanding the importance of export certification is essential for companies aiming to thrive in the competitive automotive mold landscape.

Obtaining export certification in the automotive industry is crucial for manufacturers aiming to market their products globally. Certification ensures that automotive molds meet international quality standards and compliance requirements. The first step in this process is understanding the specific regulations in the target markets. Different countries may have unique requirements regarding safety, environmental impact, and performance standards.

Manufacturers should conduct thorough research to familiarize themselves with these regulations to avoid costly delays in the export process.

Obtaining export certification in the automotive industry is crucial for manufacturers aiming to market their products globally. Certification ensures that automotive molds meet international quality standards and compliance requirements. The first step in this process is understanding the specific regulations in the target markets. Different countries may have unique requirements regarding safety, environmental impact, and performance standards.

Manufacturers should conduct thorough research to familiarize themselves with these regulations to avoid costly delays in the export process.

Another key requirement for export certification is proper documentation. This includes technical specifications, testing reports, and proof of compliance with relevant standards. Manufacturers often need to collaborate with third-party certification bodies to validate that their products meet the necessary criteria. Additionally, maintaining ongoing quality control throughout production is essential, as this not only aids in obtaining certification but also reinforces a manufacturer's reputation for reliability in the global market. By being proactive in understanding requirements and ensuring compliance, automotive mold manufacturers can navigate the complexities of export certification effectively.

In today's competitive global market, quality assurance plays a pivotal role in enhancing the competitiveness of automotive molds. With the global quality assurance service market projected to reach USD 22.67 billion by 2033, the emphasis on maintaining high standards is clear. Automotive manufacturers must focus on rigorous testing, inspection, and certification processes to ensure that their products meet international standards. This not only ensures consumer safety but also builds trust with global partners.

**Tips:** To remain competitive, companies should consider investing in quality assurance consulting services, which can provide expert guidance on compliance and best practices. Additionally, embracing accreditation can help small and medium-sized enterprises (SMEs) gain access to wider markets, leveraging their certified processes as a strategic tool for growth.

Furthermore, collaboration among industry leaders can enhance quality standards across the supply chain. The establishment of centers like the African Quality Assurance Center, aimed at boosting intra-African trade, exemplifies how strategic partnerships can improve product quality and market access. By prioritizing quality assurance, automotive mold manufacturers can navigate export certification more effectively, ensuring their place in the dynamic global landscape.

| Country | Certification Standard | Quality Assurance Metrics | Market Share (%) | Competitive Position |

|---|---|---|---|---|

| USA | ISO 9001 | Defect Rate (ppm) | 30% | Leader |

| Germany | VDA 6.3 | First Pass Yield (%) | 25% | Challenger |

| Japan | JIS Q 9001 | Supplier Quality Rating | 20% | Niche Player |

| South Korea | KS Q 9001 | On-Time Delivery Rate (%) | 15% | Emerging |

| China | GB/T 19001 | Process Compliance (%) | 10% | Developing |

Navigating the certification process in the automotive industry can often seem like a daunting task for manufacturers looking to establish a strong presence in the global market. With the complexity of regulations and standards varying from region to region, it's critical for companies to understand the required steps to ensure their products meet necessary certifications. Manufacturers should begin by conducting an in-depth analysis of the specific requirements pertinent to the markets they wish to enter, including safety and quality standards, environmental considerations, and technology certifications.

Recently, a company exemplifying success in global automotive certification efforts has been at the forefront of advancing automotive technology. Their comprehensive approach to the certification process has further solidified their role as a thought leader in the field. By leveraging new insights from industry reports, such as the latest white paper on certification practices, manufacturers can streamline their processes and improve their chance of success in diverse markets. Emphasis on collaboration and industry partnerships will also be vital as companies navigate this landscape, ensuring they are aligned with the latest advancements and expectations in the automotive sector.

In recent years, several Chinese manufacturers of automotive molds have achieved remarkable success in the global market by obtaining the necessary export certifications. These certifications not only enhance the credibility of their products but also ensure compliance with international standards, making them more attractive to foreign buyers. For instance, a Chinese company specializing in high-precision plastic molds leveraged its ISO certification to penetrate the European market. This certification acted as a key differentiator, allowing them to showcase their commitment to quality and safety, which are paramount in the automotive industry.

Another notable case study involves a manufacturer that focused on electric vehicle (EV) molds. By obtaining specific certifications related to EV production standards, this company was able to secure contracts with major automakers in North America. Their proactive approach to certifications not only opened doors for collaboration but also positioned them as a reliable partner in the rapidly evolving EV sector. These examples highlight that, in an increasingly competitive global landscape, the strategic pursuit of export certifications is crucial for Chinese automotive mold manufacturers aiming for success beyond their domestic market.