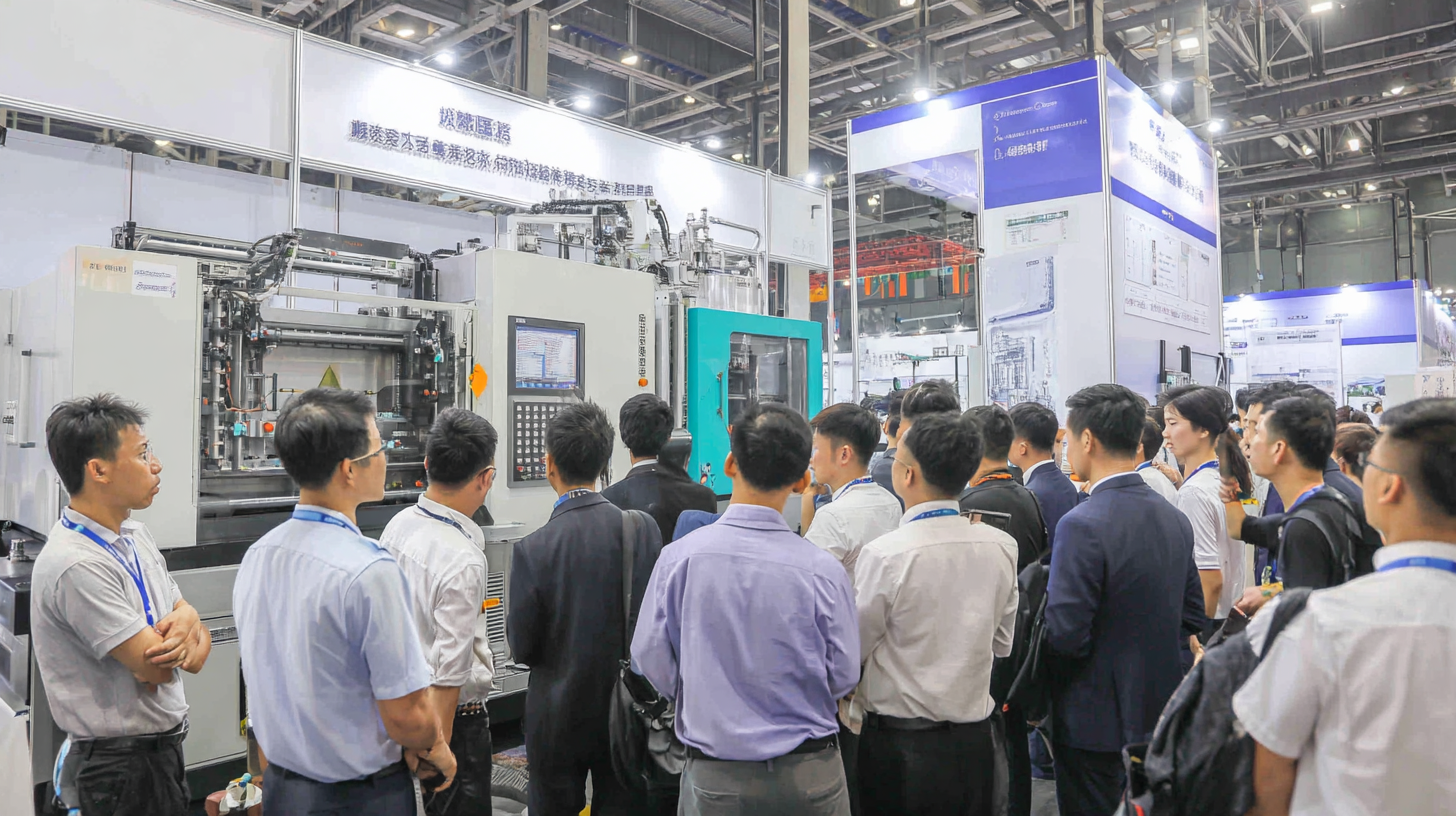

As the 138th Canton Fair approaches in 2025, the spotlight is on the growing adoption of advanced manufacturing techniques, particularly the "Advantages of Stacked Molds." Industry reports indicate that the global injection molding market is projected to reach USD 336.26 billion by 2027, driven by innovations that enhance productivity and reduce costs (Market Research Future, 2022). Stacked molds, which allow for multiple cavity configurations within a single mold, are gaining traction as they significantly optimize production efficiency and material usage. According to a recent study by Plastics Technology, companies that implement stacked molding techniques have reported a reduction in cycle times by up to 30%, demonstrating substantial improvements in overall operational capacity. This competitive edge not only enables manufacturers to meet increasing demand but also positions them strategically against global competitors at industry events like the Canton Fair, where showcasing cutting-edge technologies can lead to lucrative business opportunities.

Utilizing stacked molds in product design offers significant advantages that streamline production and enhance efficiency. Stacked molds are engineered to simplify the design process, allowing for quicker iterations and modifications. This adaptability is crucial for manufacturers looking to respond rapidly to market demands and customer needs. By integrating these molds into their workflows, companies can minimize the time it takes to bring products to market, thereby gaining a competitive edge.

Furthermore, the use of stacked molds reduces maintenance challenges and production costs. With features designed for easy centering and assembly, these molds facilitate a smoother operational flow. Manufacturers can achieve high-volume outputs while maintaining consistent quality across their products. This combination of efficiency and reliability not only boosts productivity but also reinforces the capacity for innovation in product design. As industries continue to evolve, the benefits of stacked molds will undoubtedly play a pivotal role in shaping successful manufacturing strategies.

At the 138th Canton Fair in 2025, stacked molds emerged as a game-changing innovation in the manufacturing sector. These molds, designed to maximize production efficiency, are an integral part of modern injection molding practices. According to a report by Smithers Pira, the global market for mold technology is expected to reach $50 billion by 2026, driven largely by advancements in manufacturing processes and materials. Stacked molds enable manufacturers to produce multiple parts simultaneously, reducing cycle times by up to 30%. This not only enhances productivity but also lowers operational costs, making it a compelling choice for businesses looking to maintain a competitive edge.

The innovative features of stacked molds showcased at the fair include improved cooling systems and ergonomic designs that facilitate quicker setup and changeover times. Research from the American Society for Plastics Engineers highlights that enhanced cooling efficiency can decrease production time significantly, contributing to better overall output quality. Furthermore, with the growing demand for customized products, the adaptability of stacked molds to various mold configurations allows manufacturers to cater to diverse client needs while optimizing resource utilization. This versatility positions stacked molds as a pivotal asset in the increasingly competitive landscape of manufacturing.

This chart illustrates the key advantages of stacked molds showcased at the 138th Canton Fair 2025, highlighting critical factors such as cost efficiency, production speed, material flexibility, customization options, and quality consistency.

The 138th Canton Fair in 2025 spotlights the significant advancements in manufacturing technology, particularly the growing popularity of stacked molds. These innovative molds present a remarkable solution for businesses aiming to enhance cost efficiency while boosting production speed. By integrating multiple cavities into a single mold design, manufacturers can produce a higher volume of parts in less time, ultimately reducing the cycle time and operational costs involved in production processes.

Additionally, stacked molds enable the simultaneous production of different components, fostering versatility in manufacturing operations. This feature not only allows companies to diversify their product offerings but also to respond promptly to market demands without incurring additional setup costs. As manufacturers seek to optimize their operations and improve their competitive edge, the adoption of stacked molds at events like the Canton Fair underscores the importance of embracing technological advancements to remain relevant and efficient in today’s fast-paced market.

The rising popularity of stacked molds is reshaping the manufacturing landscape, particularly highlighted at the 138th Canton Fair 2025. These molds not only optimize production efficiency but also enhance product quality, making them a preferred choice for manufacturers seeking competitive advantages. According to recent industry reports, the stacked mold market is projected to reach significant growth, driven by advancements in technology and increased demand for complex shapes and features in various sectors.

One of the key reasons for the growing appeal of stacked molds is their ability to reduce cycle times, thus increasing overall productivity. Manufacturers can produce multiple parts in a single process, mitigating downtime and labor costs. Additionally, they provide flexibility in design, allowing businesses to quickly adapt to market demands. A market survey indicates that adoption of stacked mold technology can lead to a 30% increase in production efficiency for firms in the plastic and automotive industries.

Tips: When considering the transition to stacked molds, manufacturers should assess their current production capacity and identify specific areas where improvements can be made. Investing in training for staff on the latest mold design technologies can further enhance operational efficiency. Furthermore, collaborating with mold suppliers that offer robust support services can ensure a smoother implementation process, maximizing the return on investment.

The 138th Canton Fair in 2025 promises to be a significant gathering for stacked molds enthusiasts, offering invaluable networking opportunities amidst a rapidly evolving industry. With the global mold market projected to reach $12.4 billion by 2026, driven by advancements in manufacturing technologies and increasing demand for precision molds, attendees will find themselves in the perfect environment for fostering professional connections. Participants will be able to engage in discussions with leading manufacturers, engineers, and innovators, all of whom are keen to share insights on the latest trends and technologies surrounding stacked molds.

To make the most out of networking at the Canton Fair, it’s essential to prepare ahead. **Tip 1:** Identify key exhibitors and speakers related to stacked molds. Create a plan to visit their booths and attend their presentations, ensuring valuable face-to-face interactions. **Tip 2:** Bring plenty of business cards and be ready to discuss your projects and interests clearly, as personal introductions can lead to meaningful collaborations. Additionally, leveraging social media platforms like LinkedIn during the fair can help in reconnecting with industry peers after the event.

As the stacked mold sector continues to gain traction, those who actively participate in networking at events like the Canton Fair will benefit from enhanced visibility in the market. Engaging with fellow professionals could lead to mentorship opportunities or partnerships, ultimately propelling careers and businesses forward in this competitive landscape.

| Feature | Advantage | Benefit to Users | Networking Opportunity |

|---|---|---|---|

| Design Flexibility | Modular design allows customization | Tailored solutions for specific needs | Meet with designers and engineers |

| Cost Efficiency | Reduced material waste | Lower production costs | Connect with suppliers and manufacturers |

| Enhanced Durability | Improved material choice | Longer lifespan of molds | Engage with industry experts |

| Rapid Prototyping | Faster development cycles | Accelerated time to market | Collaborate with other innovators |

| Market Adaptability | Versatile design for different products | Broader market reach | Network with diverse industry stakeholders |