Choosing the right agricultural machinery molds is essential for efficiency and productivity in farming. According to industry reports, the global agricultural machinery market is expected to reach $200 billion by 2025. Selecting the proper molds can drastically enhance the quality and durability of farm equipment.

The effectiveness of agricultural machinery molds lies in their design and material composition. Research shows that using high-quality molds can improve output by 20% or more. Farmers need to consider factors like crop types and soil conditions when making their choices. Sometimes, the wrong mold can lead to machinery failures, resulting in costly downtimes.

Additionally, the market is evolving. With new technologies, molds are becoming more specialized. This complexity makes selection more challenging. Farmers must stay informed about innovations and best practices in mold selection. Without adequate knowledge, one may overlook crucial details that determine success. Investing time in learning can lead to significant long-term benefits in agricultural practices.

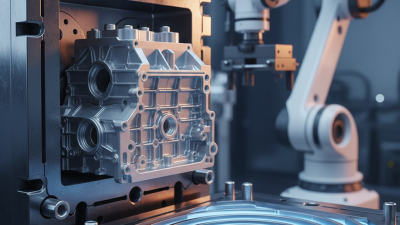

Understanding the importance of agricultural machinery molds in farming is crucial for productivity. According to a report by the International Journal of Agricultural Technology, the right molds can enhance efficiency by up to 30%. They are vital for producing high-quality parts that directly impact machinery performance. For example, precision molds reduce wear and tear on equipment, leading to longer service life.

Tips: Always assess the specific requirements of your farming operation. Different tasks require different molds. A one-size-fits-all approach may not yield the best results. Inadequate molds can result in part failures, which can halt operations and increase costs.

Additionally, consider the material used for the molds. Research indicates that molds made from high-grade steel offer better durability against harsh agricultural conditions. They withstand extreme temperatures and pressures better than standard options. However, choosing expensive materials may strain budgets, which is a common concern among farmers.

Tips: Balance cost and quality. Making informed choices can prevent waste and save money in the long run. Evaluate your options thoroughly to ensure you select molds that meet both performance and budgetary needs.

Choosing agricultural machinery molds requires careful consideration of several key factors. Material selection plays a pivotal role. High-quality materials enhance durability and ensure precision. According to a recent report by Industry Research, over 70% of machinery failures are linked to inferior materials. Thus, prioritizing quality is essential.

Another critical aspect is the compatibility of molds with specific machinery. It’s vital to ensure that the molds fit seamlessly with existing equipment. Misalignments can lead to inefficiencies. Data shows that mismatched molds can reduce productivity by up to 30%. Evaluating compatibility can save time and resources in the long run.

Finally, consider the mold design. A well-designed mold optimizes production processes and minimizes waste. However, many businesses overlook this vital aspect, leading to costly errors. As highlighted in several industry case studies, companies that invest in advanced mold designs typically see a 25% improvement in operational efficiency. Make informed choices to enhance agricultural productivity and reduce long-term costs.

| Factor | Description | Importance Level | Examples |

|---|---|---|---|

| Material Type | Choosing the right material ensures durability and effectiveness of the molds. | High | Steel, Aluminum, Plastic |

| Mold Design | The design must match the specific agricultural product being produced. | Critical | Shape, Size, Complexity |

| Production Volume | Consideration of how many units will be produced can influence mold choice. | Medium | Low, Medium, High Volume |

| Budget | Ensure that the chosen molds fit within the allocated budget for machinery. | High | Economical, Mid-range, Premium |

| Maintenance Requirements | Choose molds that require manageable maintenance for long-term use. | Medium | Easy, Moderate, Requires Specialist |

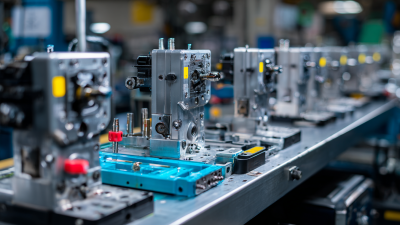

Choosing the right agricultural machinery molds is crucial. Different types of molds serve various purposes. Understanding these differences helps optimize production processes.

Common types include injection molds, blow molds, and compression molds. Injection molds are often used for precise parts. They are great for creating complex shapes. Blow molds typically produce hollow items, like tanks or bottles. Compression molds are useful for larger components. Each type has specific benefits and limitations.

**Tip:** Consider the material requirements for your projects. Different molds work better with certain materials. Matching the mold type with the material can enhance durability and performance.

The choice of mold also affects production costs. Some molds require higher initial investments but could lower long-term costs. Reflect on your budget and production goals. Think about how much you're willing to invest upfront versus potential savings.

**Tip:** Don't forget to assess the quality of each mold type. Poor-quality molds can lead to inconsistencies. Over time, this might cause more waste. Reflect on past experiences with molds before making your decision.

Choosing the right materials for agricultural machinery molds is crucial. Durability and performance greatly impact efficiency. When selecting materials, consider the type of crops and soil conditions. Molds need to withstand various stresses during their usage.

Tips: Always evaluate the environmental conditions your molds will face. Will they be exposed to moisture or chemical fertilizers? This can affect material choice. Common options include steel and aluminum, known for their strength.

Think about the long-term effects of wear and tear. Some materials may degrade faster under harsh conditions. It’s also essential to assess the manufacturing process. Certain materials may be more costly to mold. Reflect on if the initial investment is worth it for your needs.

Consider testing prototypes before committing to a large order. This approach helps identify potential flaws early on. Sometimes, materials that seem durable aren't the best fit. Always prioritize real-world performance over theoretical specifications.

Investing in quality agricultural machinery molds can seem daunting. The choices available often lead to confusion. Understanding the cost-benefit analysis is crucial. Quality molds can enhance productivity. They ensure a better fit and higher durability. In the long run, this can reduce maintenance costs significantly. However, the initial investment is higher.

Consider the materials used. High-quality molds may use advanced materials, increasing their cost. But, they can withstand wear and tear longer. This longevity can lead to fewer replacements. Short-term savings might tempt many to choose cheaper options. Yet, these often result in greater long-term expenses.

Track and evaluate your operations. Over time, assess the performance of your molds. Are they meeting your needs? Have they decreased downtime? Reflecting on these questions can offer insights. Sometimes, the cheapest option does not deliver the best value. Balancing cost and quality is key in your decision-making process.