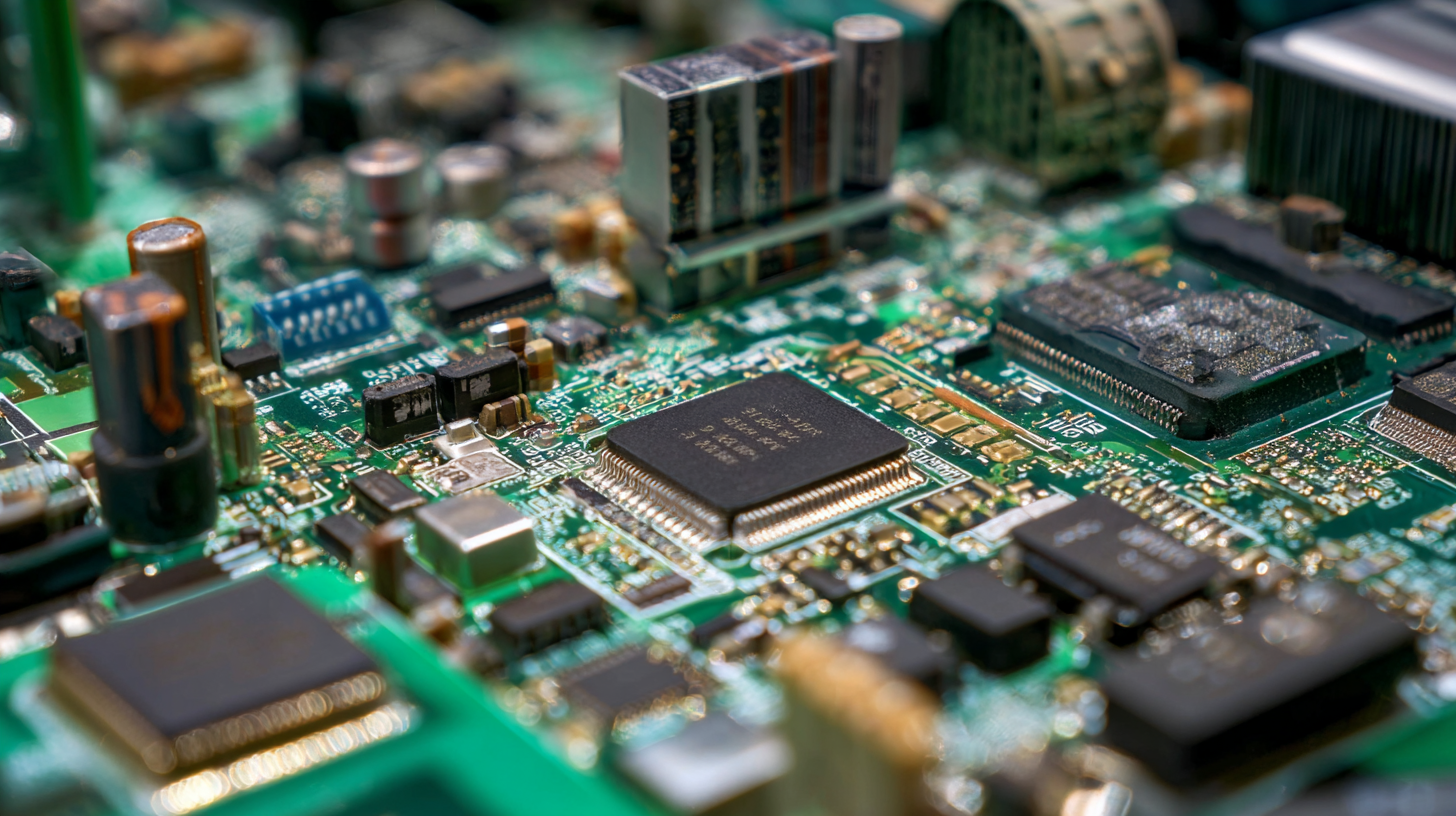

In today's fast-paced technological landscape, selecting the right tools for your projects is crucial, especially when it comes to the foundational elements like Electronic Hardware Molds. These molds serve as the backbone for various electronic components, impacting both their functionality and overall durability. With a myriad of options available, choosing the best Electronic Hardware Molds can often feel overwhelming. This blog aims to simplify the decision-making process by providing key insights into factors you should consider, including material compatibility, design intricacies, and production efficiency. By understanding these critical aspects, you can ensure that your projects not only meet your specifications but also stand the test of time in performance and quality. Whether you are a seasoned professional or a newcomer in the field, this guide will equip you with the knowledge needed to make informed choices.

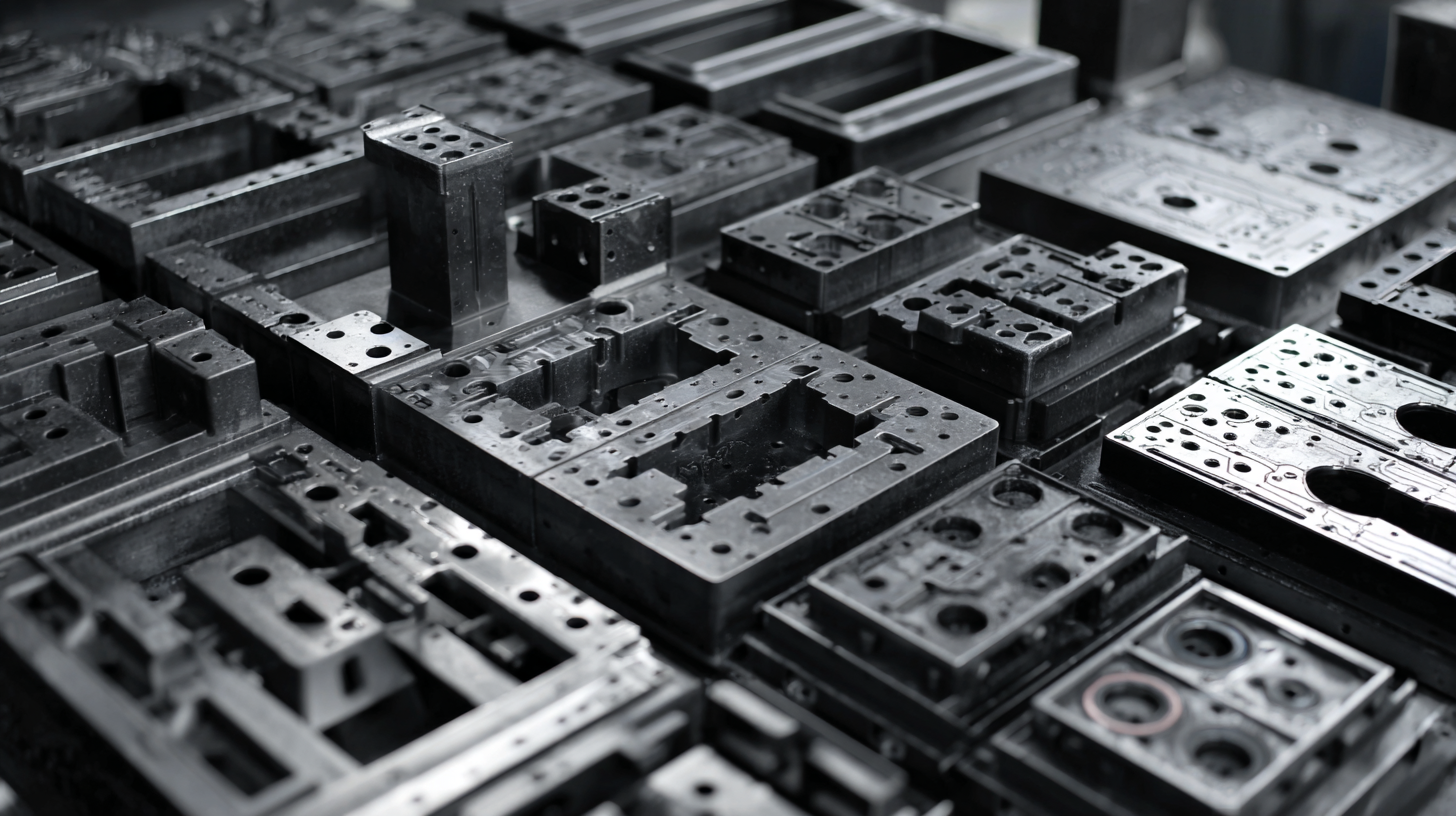

When selecting electronic hardware molds for your projects, several factors play a crucial role in ensuring you achieve optimal results. First and foremost, the material of the mold is vital. Options such as aluminum, steel, or even composite materials each come with their own advantages and disadvantages. Aluminum molds are lighter and more cost-effective for lower production runs, while steel molds offer durability and longevity for high-volume manufacturing. Understanding your project's requirements will help in choosing the right material.

Another critical factor is the design complexity of the mold. The intricacy of your electronic components can dictate whether you need a simple or complex mold design. Consider elements such as wall thickness, draft angles, and cooling channels, as these affect both the quality of the final product and the efficiency of the manufacturing process. Engaging with experienced mold designers who can provide insights on overcoming design challenges can significantly enhance the molding process, delivering better performance and precision in your electronic hardware projects.

When selecting electronic hardware molds for your projects, it’s important to understand the various types available and their specific applications. Traditional molds, such as those used for injection molding, play a vital role in producing components for consumer electronics and automotive industries. These molds utilize thermoplastic and thermoset materials, providing strong and versatile components. Moreover, the recent advancements in 3D electronics and additive manufacturing have opened new frontiers in mold design, allowing for innovative product differentiation and the integration of electronics directly into mold structures.

Another significant trend is the rise of flexible and printed electronics, which is expected to transform several sectors. The emergence of technologies such as Lab-on-PCB showcases how integrated systems can lead to more efficient and compact electronic solutions. Additionally, in-mold electronics are becoming increasingly popular, facilitating the development of sophisticated human-machine interfaces. As you consider the best electronic hardware molds for your projects, be sure to explore these emerging technologies and their impactful applications, ensuring your designs are at the forefront of innovation.

When selecting electronic hardware molds, the choice of material is pivotal to ensure durability and functionality. Among the various options available, high-grade aluminum is a popular choice due to its excellent heat conduction and corrosion resistance.

Aluminum molds are lightweight yet robust, making them ideal for high-volume production where precision and repeatability are essential. Their ability to withstand repeated use without degrading makes them a top contender for projects requiring longevity.

Another excellent material option is steel, particularly for molds that will experience significant wear and tear. Steel molds, though heavier and often more expensive than aluminum, offer unmatched durability and can handle intricate designs with high precision. They are particularly suited for high-pressure applications, providing the strength needed for complex shaping processes.

Additionally, materials like silicone and polyurethane can be considered for softer and more flexible molds, allowing for easy release and detailed shapes. Ultimately, the choice of material should align with the specific requirements of your project, balancing performance, longevity, and cost-effectiveness.

When selecting electronic hardware molds for your projects, balancing cost-effectiveness with quality is pivotal. According to research, many industries strive to maintain a fine equilibrium between performance and budget—often referred to as the Iron Triangle of product development. This triangle asserts that teams can only reliably deliver two of the three elements: fast, good, and cheap. With the lean startup process gaining traction, companies are encouraged to explore iterative approaches that promote rapid prototyping without compromising quality or incurring excessive costs.

Recent studies have highlighted how the integration of quality improvement practices can significantly impact cost-effectiveness. For instance, a mathematical modeling study found that decentralizing childhood tuberculosis diagnosis in high-incidence countries not only improved patient outcomes but also optimized budget allocations—essentially demonstrating that investing in quality can yield long-term savings. Similarly, analyses have shown that certain psychiatric rehabilitation approaches can enhance social participation at sustainable costs. These findings reinforce the idea that when it comes to choosing electronic hardware molds, prioritizing quality within a controlled budget can lead to superior project outcomes and greater overall efficiency.

When embarking on the journey to select the best electronic hardware molds for your projects, effective collaboration with mold manufacturers is crucial for achieving success. According to a report by MarketsandMarkets, the global mold market is projected to reach $6.4 billion by 2026, emphasizing the increasing importance of selecting the right partners in mold manufacturing. A seamless collaboration can significantly impact the quality and efficiency of production, ensuring that your project meets both deadlines and standards.

**Tip:** Clearly communicate your project specifications and expectations during initial discussions with mold manufacturers. Providing detailed design documents and usage scenarios can help manufacturers understand your needs better, enabling them to offer tailored solutions.

Moreover, it is essential to establish a feedback loop throughout the development process. A survey by Deloitte found that companies with strong collaborative practices in supply chain management can see performance improvements of up to 30%. This can include regular check-ins and updates on progress, allowing for adjustments and fine-tuning based on early prototypes. Emphasizing open communication not only minimizes misunderstandings but also fosters trust and innovation.

| Dimension | Material | Tolerance | Surface Finish | Lead Time |

|---|---|---|---|---|

| 100mm x 50mm | Aluminum | ±0.05mm | Anodized | 4 weeks |

| 200mm x 100mm | Steel | ±0.03mm | Polished | 6 weeks |

| 150mm x 75mm | Thermoplastic | ±0.1mm | Matte | 3 weeks |

| 300mm x 150mm | Copper | ±0.02mm | Chrome Plated | 5 weeks |