The 138th Canton Fair in 2025 presents a pivotal opportunity for industry leaders to delve into the "Advantages of Stacked Molds." As reported by the International Plastics Association, the global market for injection molding is projected to reach $350 billion by 2027, driven by innovations that enhance efficiency and reduce production costs. Stacked molds offer a unique approach by allowing manufacturers to simultaneously produce multiple components, thereby optimizing the use of material and energy. Recent studies indicate that the adoption of stacked molding techniques can reduce cycle times by up to 30%, significantly improving throughput and profitability. This important trade fair not only showcases cutting-edge advancements in mold technologies but also serves as a platform for networking and knowledge exchange, emphasizing the crucial role of stacked molds in the future of manufacturing.

Exploring the innovative features of stacked molds at the upcoming Canton Fair 2025 highlights the advancements in manufacturing efficiency and product quality. Stacked molds, which allow for simultaneous production of multiple items, can significantly reduce cycle times and material waste, leading to a more sustainable manufacturing process. According to a report by the International Journal of Advanced Manufacturing Technology, employing stacked molds can increase production efficiency by up to 40%, making them a valuable asset for modern manufacturers.

Moreover, the introduction of smart technologies into stacked molds is reshaping the industry landscape. These molds are now equipped with sensors and IoT capabilities, enabling real-time monitoring and data analytics. This integration allows manufacturers to predict maintenance needs and optimize production schedules, which, as noted by the Global Manufacturing Insights survey, can reduce downtime by approximately 30%. As the industry evolves, the emphasis on innovation and sustainability through enhanced features in stacked molds positions them as a cornerstone for future manufacturing practices. The Canton Fair 2025 will serve as a platform for showcasing these advancements, offering insights into how these technologies can impact various sectors.

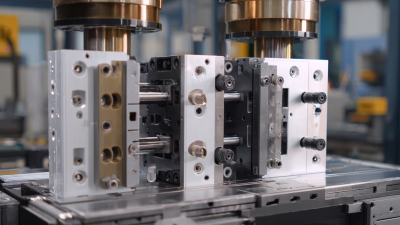

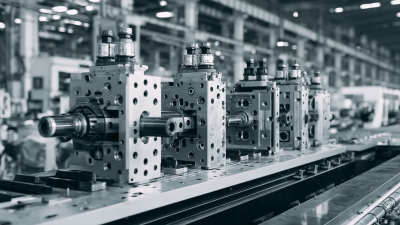

Stacked molds have emerged as a revolutionary technology in the manufacturing sector, particularly highlighted at the 138th Canton Fair in 2025. These molds enable manufacturers to create multiple parts simultaneously by stacking them, thereby significantly reducing production time and increasing output. This innovation allows for greater flexibility in design and accelerates the prototyping phase, making it easier for companies to adapt to changing market demands swiftly.

Moreover, the efficiency gained from using stacked molds translates directly into cost savings for manufacturers. By maximizing the use of available space and optimizing the manufacturing process, companies can lower their operational costs while maintaining high-quality standards. The reduced cycle times achieved through stacked molding also mean that businesses can meet tighter deadlines, ultimately enhancing their competitive edge. In an industry that increasingly prioritizes quick turnaround and customer satisfaction, the role of stacked molds in enhancing production efficiency cannot be overstated.

The shift towards environmental sustainability in manufacturing has been accelerated by advancements in technologies such as stacked molds. At the 138th Canton Fair 2025, industry leaders highlighted that stacked molds can significantly reduce material waste and energy consumption. According to a report by the International Plastics Association, using stacked molds can lead to a reduction of up to 30% in raw material usage, thereby minimizing the ecological footprint of production processes.

Moreover, these molds enhance manufacturing efficiency by allowing simultaneous production of multiple components, which not only speeds up the assembly process but also optimizes factory floor space. A study from the Global Manufacturing Report indicates that employing stacked molds can improve production output by roughly 25%, all while lowering operational costs. This dual benefit of enhancing productivity while promoting environmental responsibility positions stacked molds as a key player in the future of sustainable manufacturing practices, making them an attractive option for industry stakeholders aiming to meet both economic and ecological goals.

This chart depicts the environmental benefits of using stacked molds as showcased at the 138th Canton Fair 2025. The data highlights reductions in material waste, energy consumption, and overall production costs, emphasizing the sustainable advantages of this technology.

The growing consumer demand for advanced mold solutions is reshaping the industry landscape, particularly highlighted at the 138th Canton Fair in 2025. Stacked molds are emerging as a pivotal innovation, enabling manufacturers to optimize production efficiency while meeting intricate design requirements. These advanced solutions not only cater to the rising expectations from consumers for quality and precision but also contribute to sustainability efforts through reduced material waste.

Tips: Explore how stacked molds can significantly shorten lead times and minimize costs. Additionally, by integrating automation in their production processes, companies can further enhance their operational efficiencies, responding deftly to shifting market trends.

The interplay of technological advancements and evolving consumer preferences underscores the necessity for businesses to stay responsive to market dynamics. With industries such as the semiconductor and packaging sectors anticipating robust growth, the integration of advanced molding techniques will be essential. Companies should invest in research and development to innovate and align their offerings with the future demands of the marketplace.

Tips: Collaborating with technology partners can provide insights into emerging trends, helping businesses refine their product strategies. Keeping a pulse on sustainability trends will also better position companies within the increasingly eco-conscious consumer base.

The 138th Canton Fair, set to be held in 2025, offers mold manufacturers a unique platform for networking and collaboration. As an industry that is poised for significant growth—projected to reach a market value of $7.5 billion by 2026—attendees will have the opportunity to connect with key players in the mold sector. The fair is expected to attract over 25,000 exhibitors and more than 200,000 visitors, providing an ideal environment for forging new partnerships and exploring innovative technologies, particularly in stacked mold designs which can enhance production efficiency.

Networking at the Canton Fair can yield substantial benefits for mold manufacturers. According to a recent report by Grand View Research, the increasing demand for customized molds in various industries, including automotive and consumer goods, necessitates collaboration among manufacturers to meet market needs. Engaging with peers and experts at the fair will enable companies to share insights about industry trends, adapt to emerging technologies, and discuss best practices. Furthermore, leveraging the event's platforms for knowledge exchange can be crucial for businesses looking to innovate their product offerings and streamline operations in an increasingly competitive landscape.