In recent years, Advanced Mold Technology has emerged as a pivotal innovation in modern manufacturing, driving efficiency and precision across various industries. According to a 2022 report by MarketsandMarkets, the global injection molding market is projected to reach USD 340 billion by 2026, with a significant portion attributed to advancements in mold technologies that enhance production capabilities and product quality. The integration of smart manufacturing techniques and automation within advanced molds has not only streamlined processes but also reduced material waste and cycle times, positioning companies to meet the escalating demand for higher quality and more complex designs. As manufacturers increasingly adopt these innovative techniques, the competitive landscape is rapidly evolving, highlighting the critical role that Advanced Mold Technology plays in fostering growth and sustainability in the manufacturing sector.

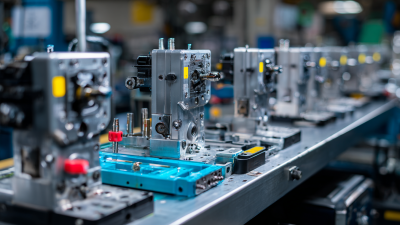

Advanced mold technology has emerged as a pivotal element in modern manufacturing, driven by the high demand for precision, efficiency, and sustainability. This technology encompasses a range of techniques and materials designed to enhance the manufacturing process, particularly in the production of complex components. Key concepts in advanced mold technology include injection molding, blow molding, and rotational molding, each offering unique advantages in terms of scalability and production speed. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $300 billion by 2025, underscoring the growing reliance on these innovative methodologies.

Moreover, advanced mold technologies utilize state-of-the-art materials such as high-performance thermoplastics and composites, which significantly improve the durability and functionality of molded parts. The introduction of smart manufacturing processes, including the integration of Internet of Things (IoT) devices, enables real-time monitoring and optimization of mold production. A study from Deloitte highlights that companies implementing advanced manufacturing technologies can increase productivity by up to 30%. These innovations not only streamline operations but also contribute to reducing waste and energy consumption, aligning with global sustainability goals.

Advanced mold technology plays a pivotal role in elevating product quality and operational efficiency in modern manufacturing. By utilizing sophisticated materials and precision engineering, manufacturers are able to enhance the durability and performance of molded products. According to a recent report from Research and Markets, implementing advanced mold technology can boost production efficiency by up to 25% while simultaneously reducing waste by 30%. This dual benefit not only drives down costs but also supports sustainable manufacturing practices, essential in today’s market.

**Tip:** When considering the integration of advanced mold technology, it’s crucial to evaluate the material specifications and tooling requirements tailored to your product needs. This ensures optimal performance and longevity.

The innovations in mold design, such as the use of conformal cooling channels and improved surface finishes, contribute significantly to cycle time reduction, which can be further reflected in customer satisfaction. A study by the American Society for Quality notes that products manufactured with advanced mold techniques can achieve a defect rate reduction of 50%. This not only improves the reliability of the products but also enhances brand reputation in an increasingly competitive landscape.

**Tip:** Collaborating with experienced mold designers can provide valuable insights into maximizing the benefits of advanced technology, resulting in a smoother transition and better end products.

| Dimension | Description | Impact on Product Quality | Impact on Efficiency |

|---|---|---|---|

| Precision Engineering | Utilization of advanced CAD/CAM software for mold design. | Ensures tighter tolerances and higher quality finishes. | Reduces material waste and lowers production time. |

| Material Advancements | Integration of new materials like high-strength polymers. | Improves durability and functionality of final products. | Enhances production speed due to faster cycle times. |

| 3D Printing Technology | Use of 3D printing for rapid prototyping of molds. | Allows for rapid iterations and improved design flexibility. | Significantly shortens the lead time for mold creation. |

| Automation and Robotics | Incorporation of automated systems in mold production. | Reduces human error, ensuring higher product consistency. | Increases output rates and lowers labor costs. |

| Smart Sensors | Implementation of IoT sensors for real-time monitoring. | Ensures quality assurance throughout the manufacturing process. | Optimizes machine performance and reduces downtime. |

The integration of innovative techniques in mold design, particularly through the use of 3D printing and smart manufacturing, has transformed modern manufacturing processes. 3D printing allows for rapid prototyping and customization of molds, enabling manufacturers to create complex geometries that were previously unattainable with traditional methods. This capability not only reduces lead times but also minimizes material waste, fostering efficiency and sustainability. As a result, businesses can respond swiftly to market demands and enhance their competitive edge.

Smart manufacturing further complements these advancements by incorporating advanced software and IoT technologies into the mold design process. By leveraging real-time data analytics and automation, manufacturers can optimize production processes, predict maintenance needs, and improve product quality. The synergy between 3D printing and smart manufacturing paves the way for greater flexibility and adaptability in mold production, allowing for faster iterations and innovations. This not only streamlines workflows but also enhances collaboration across different teams, leading to more innovative solutions in the industry.

Advanced mold technology is playing a pivotal role in promoting sustainability within the manufacturing sector. As industries increasingly adopt eco-friendly practices, the integration of innovative mold technologies is becoming essential. For example, the recent advancements in lightweight injection technologies demonstrate significant potential in reducing material waste and energy consumption during production. This not only enhances the efficiency of manufacturing processes but also aligns with global objectives to minimize environmental impacts.

According to recent industry reports, the global industrial mold market is projected to reach approximately USD 119.73 billion by 2033, reflecting robust growth driven by innovations in polymer processing and advancements in manufacturing technology. Moreover, the U.S. plastic processing auxiliary equipment market is expected to grow at a CAGR of 3.2% from 2025 to 2030, indicating a strong demand for enhanced molding solutions that facilitate sustainable manufacturing practices. As companies continue to invest in advanced molding capabilities, they are well-positioned to address the increasing consumer demand for sustainable products while remaining competitive in a rapidly evolving market.

This chart illustrates the key benefits of Advanced Mold Technology in modern manufacturing, highlighting areas such as energy efficiency, waste reduction, production speed, cost savings, and quality improvement. Each benefit is represented by a percentage, showcasing its significance in achieving sustainability in manufacturing.

Advanced mold technology plays a pivotal role in shaping Industry 4.0, as it harmonizes the digital and physical realms of manufacturing. The integration of smart factories has become a global trend, reflecting a shift towards automated and controlled production environments. According to a recent Deloitte report, the convergence of digital and physical systems enables manufacturers to optimize processes, reduce waste, and enhance product quality. This transformation is essential for tackling current challenges faced by the industry, such as labor shortages and fluctuating demand.

As we anticipate future trends, advanced mold technology is set to revolutionize various sectors, including machinery and electronics manufacturing. The 2024 report on China’s machine tool industry highlights the extensive application of conventional machining tools which cater to diverse precision requirements. This indicates a growing need for precision in mold manufacturing, further supported by technological innovations that improve efficiency and adaptability. Rising industrial demands coupled with the trend towards sustainable practices underscore the importance of advanced mold solutions, driving the evolution of manufacturing processes in an increasingly competitive landscape.