In the manufacturing landscape, the choice of die casting mold plays a pivotal role in enhancing productivity and ensuring product quality. According to a recent report by MarketsandMarkets, the global die casting market is expected to reach $91.14 billion by 2026, growing at a CAGR of 6.5%. This growth is driven by the increasing demand for lightweight materials in the automotive and aerospace sectors, where precision and durability are paramount.

Utilizing the best die casting mold not only streamlines the manufacturing process but also significantly reduces defect rates and production costs. Furthermore, a study by TechSci Research highlights that adopting advanced mold technologies can improve efficiency by up to 30%, thereby reinforcing the importance of selecting high-quality molds in the competitive market. As manufacturers strive for operational excellence, understanding the benefits of investing in top-tier die casting molds becomes essential for sustaining growth and innovation.

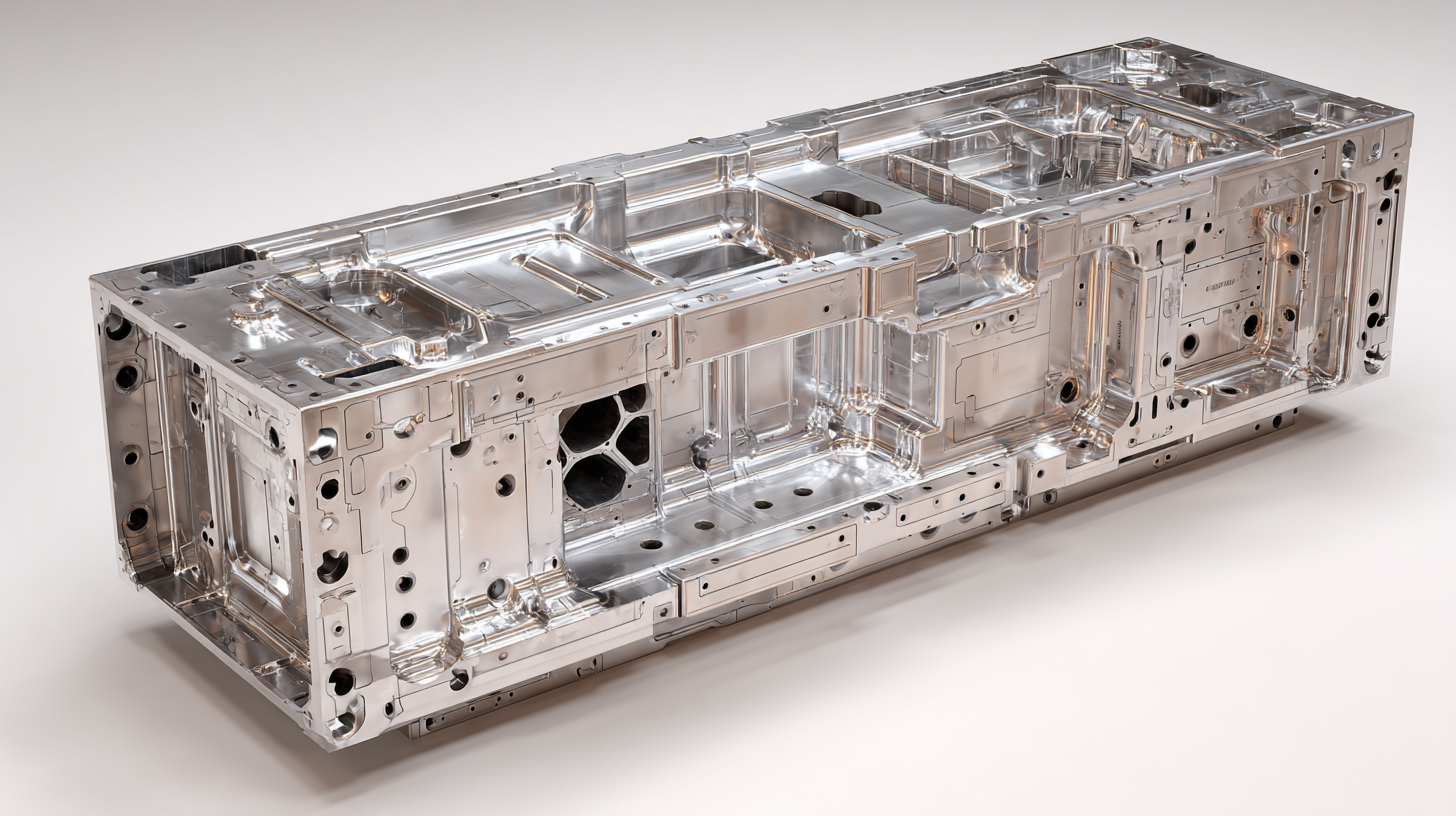

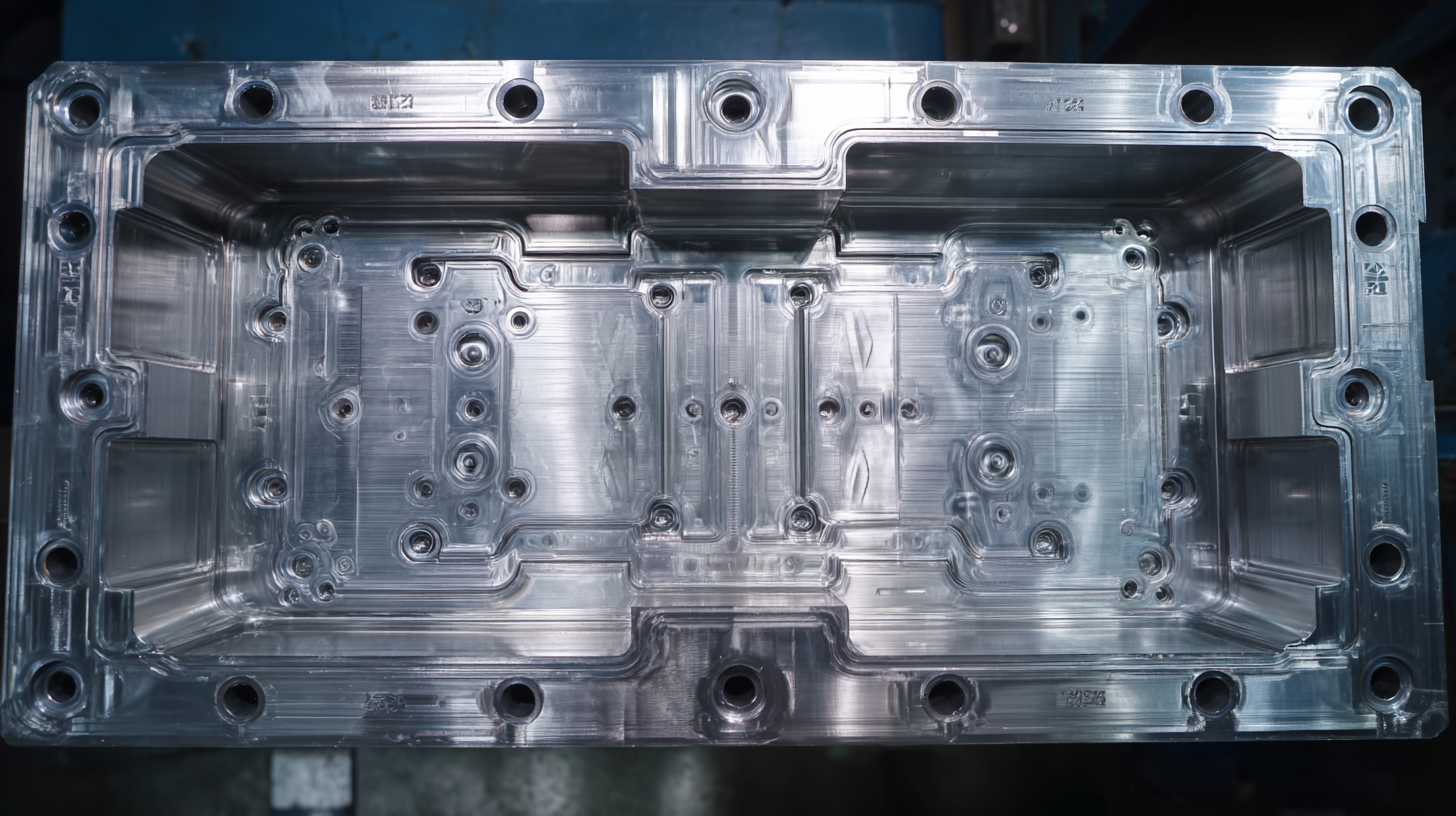

Die casting molds play a crucial role in enhancing manufacturing efficiency, making them essential for businesses aiming to optimize production processes. One of the key features to consider when selecting a die casting mold is its design precision. High-quality molds are crafted to ensure tight tolerances, which lead to better-fitting parts and minimize the need for secondary machining operations. This not only saves time but also reduces material waste, contributing to an improved bottom line.

Another important factor is the material used in the mold construction. Investing in durable materials such as steel or aluminum can significantly extend the lifespan of the molds and reduce maintenance costs. The choice of material affects heat resistance and wear-and-tear, which are critical for maintaining consistent production quality.

**Tips:** Regularly inspect and maintain your die casting molds to prevent unexpected downtime. Implementing a preventive maintenance schedule can help identify wear and tear early, ensuring that the molds remain in optimal condition. Additionally, collaborating with knowledgeable suppliers can provide insights into the latest innovations and techniques in die casting, further enhancing your manufacturing efficiency.

The use of high-quality die casting molds significantly enhances product quality and consistency in manufacturing processes. According to a report by the International Die Casting Association, utilizing advanced mold technology can reduce defects by up to 30%, resulting in a more reliable end product. These molds are engineered to provide precise dimensional accuracy, ensuring that each component produced meets stringent industry standards. This level of precision not only minimizes rework and scrap rates but also contributes to the overall efficiency of the manufacturing process.

Moreover, the best die casting molds are designed for longevity and durability, allowing for consistent production runs. A study from Market Research Future indicates that companies adopting superior mold technologies experience an increase in production efficiency by 20% or more. This improvement stems from decreased downtime and a reduction in variation across batches, ensuring that the final products maintain uniformity in quality. As industries increasingly prioritize sustainability and cost-effectiveness, investing in top-tier die casting molds proves to be a strategic move that pays dividends through enhanced product quality and consistency.

In the realm of manufacturing, investing in high-quality die casting molds can lead to significant cost-effectiveness in the long run. Although the initial investment might be higher, these molds are designed for durability and efficiency, which can drastically reduce production delays and defects over time. With a well-constructed mold, manufacturers can achieve consistent quality and precision, minimizing waste and rework costs that often eat into profits.

Moreover, using the best die casting molds streamlines the manufacturing process, allowing for faster production rates. This efficiency not only enhances output but also optimizes the resource allocation across the production line. As production cycles become quicker and more reliable, businesses can respond better to market demands, ensuring a competitive edge. Investing in exceptional die casting technology pays off by solidifying a brand's reputation for quality and reliability, ultimately driving customer loyalty and long-term success.

When selecting the right die casting mold for your manufacturing process, several critical factors should be considered to ensure optimal performance. First and foremost, the material used for the mold plays a significant role in durability and heat resistance. Options like steel or aluminum can greatly affect the lifespan of the mold, influencing not just production costs but also the quality of the final product. Choosing a mold material that complements the type of metal being cast will help in achieving precision and consistency.

Another vital aspect is the design of the mold. A well-designed mold can enhance flow characteristics, reduce defects, and improve cycle times. Factors like part geometry, draft angles, and gating systems should be meticulously analyzed during the design phase. Additionally, proper cooling and heating channels should be integrated to optimize thermal management during the casting process, resulting in better surface finish and dimensional accuracy in the end product. Addressing these considerations will not only enhance productivity but also ensure that the final output meets the highest quality standards.

In the competitive landscape of manufacturing, maximizing production speed is essential, and advanced die casting molds play a pivotal role in achieving this goal. These state-of-the-art molds are designed with precision engineering that allows for faster cycle times without compromising quality. By optimizing the flow of molten metal, manufacturers can significantly reduce waste and improve overall efficiency, ultimately leading to higher output and lower costs.

Moreover, the use of high-quality die casting molds contributes to more consistent product quality. With enhanced durability and precise dimensional control, advanced molds ensure that each casting meets stringent specifications. This reliability minimizes downtime due to defects and reduces the need for extensive rework, allowing manufacturers to maintain a seamless production flow. As a result, investing in the best die casting molds is not just about speed but also about sustaining quality and durability in the manufacturing process.