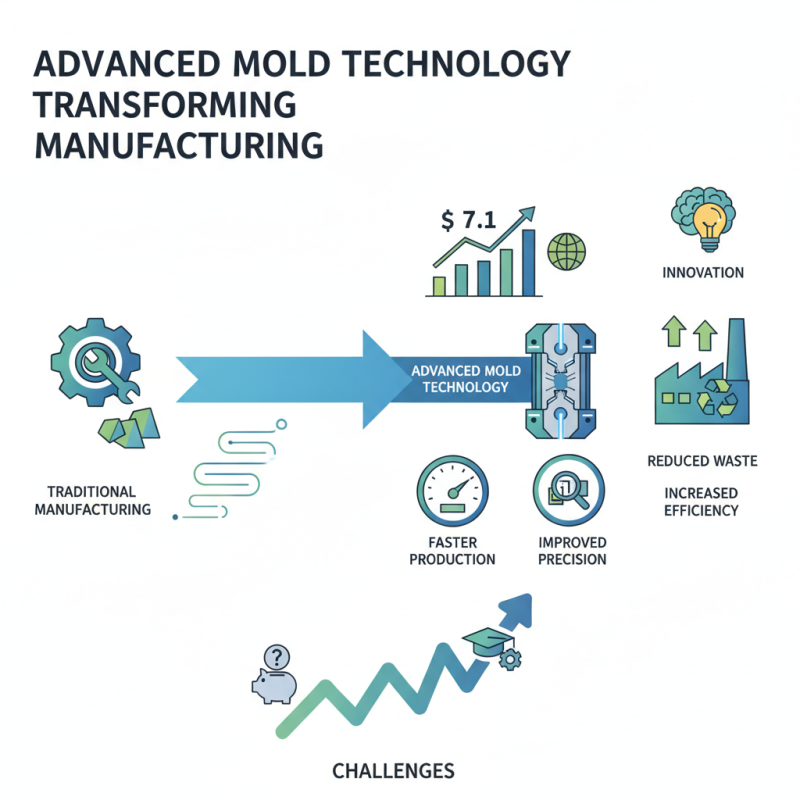

Advanced Mold Technology is revolutionizing the manufacturing landscape. According to a recent report by MarketsandMarkets, the global mold making market is projected to reach $7.1 billion by 2025. This indicates a significant investment in advanced methodologies. Industries from automotive to consumer electronics are reaping the benefits.

The adoption of Advanced Mold Technology leads to improved precision and faster production cycles. Companies can reduce waste and increase efficiency significantly. A study by Deloitte revealed that 70% of manufacturers using advanced technologies reported enhanced productivity. This data highlights the transformational potential within various sectors.

However, challenges persist. Not all manufacturers can easily transition to these advanced technologies. Investing in training and equipment can be daunting. Furthermore, there is a need for continuous improvement to keep pace with innovation. Embracing Advanced Mold Technology is crucial, yet the path may not be seamless.

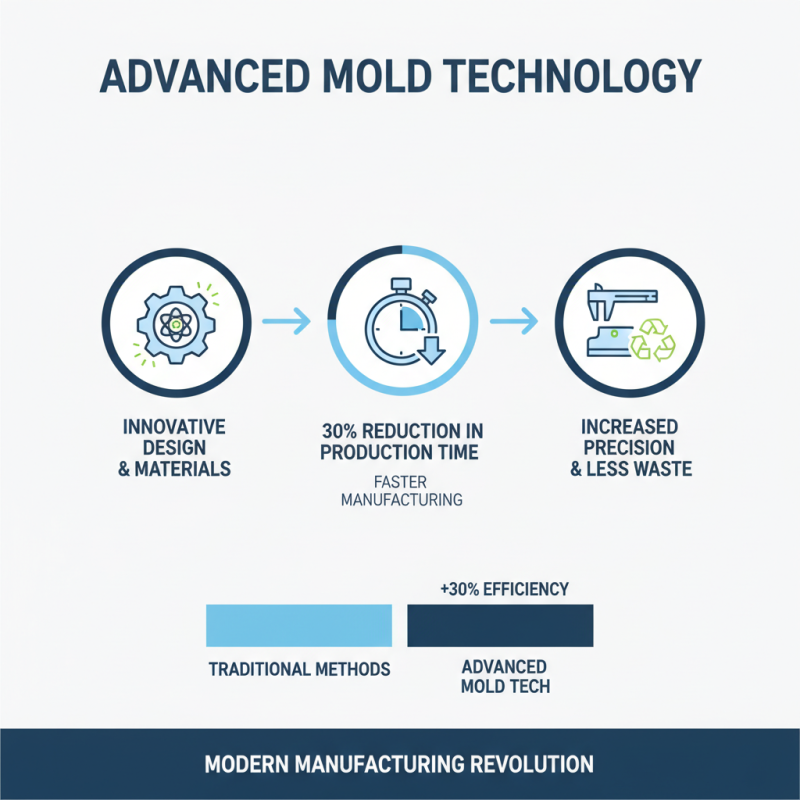

Advanced Mold Technology is a revolutionary approach in modern manufacturing. It focuses on innovative methods and materials to enhance mold design and production. According to recent industry reports, companies utilizing advanced mold techniques have seen a 30% reduction in production times. This increase in efficiency is largely due to better precision and reduced waste.

These technologies include 3D printing and advanced polymer composites. For example, 3D printing allows manufacturers to quickly create intricate mold designs that were previously impossible. This not only speeds up the process but also reduces costs significantly. However, the adoption of new technology can face resistance. Some manufacturers struggle to adapt, leading to implementation delays.

Tips: Invest in training for your team. Understanding new technologies can lead to breakthroughs. Regularly assess your processes and materials. Continuous improvement is essential. Embrace change, even if it comes with challenges. Advanced Mold Technology may require a shift in mindset, but the potential rewards are significant.

Advanced mold technology is reshaping the landscape of manufacturing. One significant advantage is efficiency. This technology enables rapid production cycles. Molds can be designed for quick changeovers to meet varying demands. Companies can reduce downtime and increase output. This process enhances overall productivity.

Another key benefit is improved precision. Advanced molds can create intricate designs with tight tolerances. This allows manufacturers to produce complex parts with high accuracy. Reducing errors during production saves time and resources. Plus, high-quality molds can withstand wear and tear. They can last longer than traditional options, which lowers costs over time.

However, there are challenges. Implementing advanced technology may require upfront investment. Not all businesses can afford the latest equipment. Training staff to use new systems can also be daunting. There might be a learning curve that slows initial productivity. Balancing costs with benefits is crucial for manufacturers. This transformation takes time and careful planning.

Advanced mold techniques are reshaping the landscape of manufacturing. By optimizing production efficiency, these methods lead to faster turnaround times. This transformation allows companies to meet market demands more effectively. Enhanced molds reduce material waste and increase product consistency. As a result, manufacturers can maintain higher quality standards while decreasing operational costs.

Tips: Regularly evaluate your mold maintenance schedule. Well-maintained equipment can significantly boost productivity and reduce downtime.

The integration of advanced technologies like 3D printing is noteworthy. It allows for more intricate designs with a shorter lead time. However, adopting such technologies requires training and adaptation. Some manufacturers face challenges in skill gaps. It's crucial to invest in staff development alongside technology upgrades.

Tips: Consider cross-training your team. Versatile skills enhance adaptability in the face of rapid changes.

Despite the advantages, some facilities struggle with the transition. Not all machinery can adapt to modern techniques easily. Older equipment may need retrofitting or replacement, which can be costly. These challenges highlight the importance of a well-thought-out implementation plan. Exploring financing options could ease this transition, allowing for a smoother upgrade process.

| Technique | Impact on Production Efficiency | Reduction in Cycle Time (%) | Improvement in Material Utilization (%) | Cost Savings (%) |

|---|---|---|---|---|

| 3D Printing Molds | Enhances design complexity and reduces weight | 30% | 20% | 15% |

| Hot Runner Systems | Reduces waste and improves cycle time | 25% | 15% | 10% |

| Injection Molding Optimization | Improves part consistency | 20% | 25% | 12% |

| Rapid Prototyping | Accelerates product design cycles | 40% | 30% | 20% |

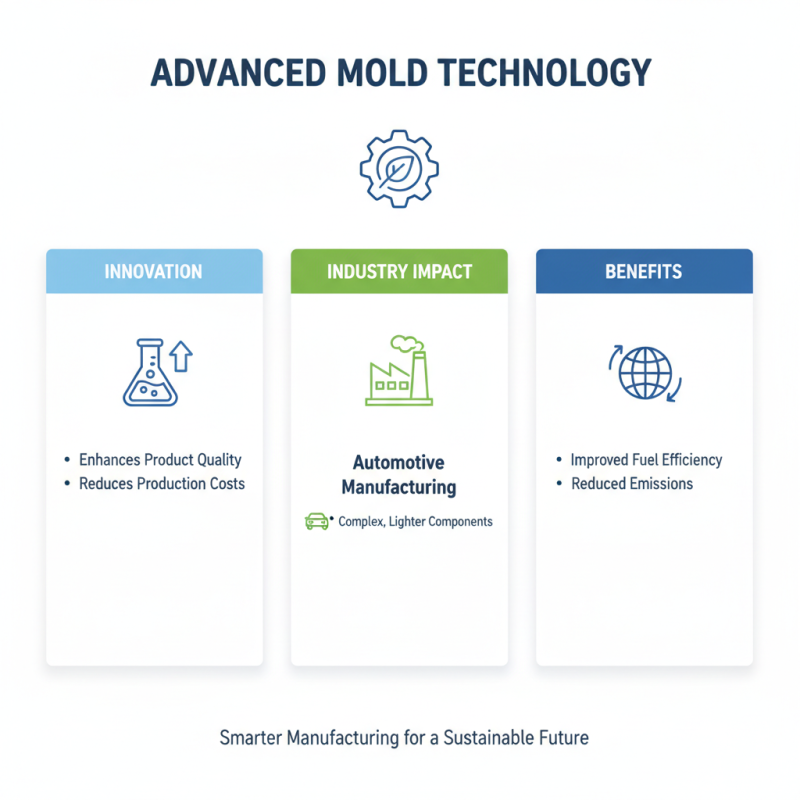

Advanced Mold Technology is revolutionizing various industries through innovative applications. This technology enhances product quality and reduces production costs. In automotive manufacturing, for example, it allows for more complex and lighter components. These parts improve fuel efficiency and reduce emissions, benefiting both manufacturers and the environment.

In electronics, Advanced Mold Technology enables the creation of intricate designs. These designs can lead to smaller devices with better performance. Think of how smartphones evolve. They get thinner but more powerful each year. This is largely due to advancements in molding technology.

Tips: Always consider scalability. Not all methods will suit every scale of operation. It's crucial to evaluate efficiency over time. Also, remember that the initial investment can be high. Balancing costs with long-term savings is essential. Weigh the pros and cons carefully.

Advanced mold technology is reshaping the landscape of manufacturing. Innovations in design and materials are driving efficiency and precision. Manufacturers are adopting advanced techniques, like 3D printing, for quicker prototype development. This technology allows for more complex shapes that traditional molds cannot achieve.

As companies focus on sustainability, eco-friendly materials are becoming more popular. Using biodegradable polymers can reduce waste significantly. Moreover, the integration of AI and automation is optimizing production processes. Machines now learn from data, improving their efficiency over time.

Tips: Always assess your current processes before transitioning to new technology. It's essential to weigh the benefits against potential costs. Employees should be trained thoroughly on new systems to avoid delays. Continuous evaluation is key to success. Keep an eye on trends, but don't rush into changes without proper analysis.