As we advance towards 2025, the realm of Electronic Mold technology is witnessing a transformative wave of innovations that could redefine manufacturing processes across various industries. Dr. Sarah Thompson, a renowned expert in the field of electronic manufacturing, emphasizes the significance of this evolution by stating, "The future of Electronic Mold technology lies in integrating smart manufacturing solutions that enhance efficiency and precision." This insight encapsulates the core motivation driving the latest trends in this sector.

The importance of Electronic Mold technology cannot be overstated, as it serves as a pivotal component in the production of high-quality electronic devices. The integration of advanced materials and automation techniques is reshaping how molds are designed and produced, ultimately leading to more sustainable and efficient manufacturing practices. This dynamic shift not only supports the technological demands of 21st-century electronics but also meets the increasing expectations for product quality and reliability.

As we explore the top trends expected to shape the Electronic Mold industry in 2025, it becomes evident that innovations such as smart sensors, artificial intelligence, and advanced simulation techniques are at the forefront, promising to enhance both functionality and productivity while reducing waste and operational costs. The convergence of these trends is set to propel the Electronic Mold sector into an era of unprecedented growth and efficiency.

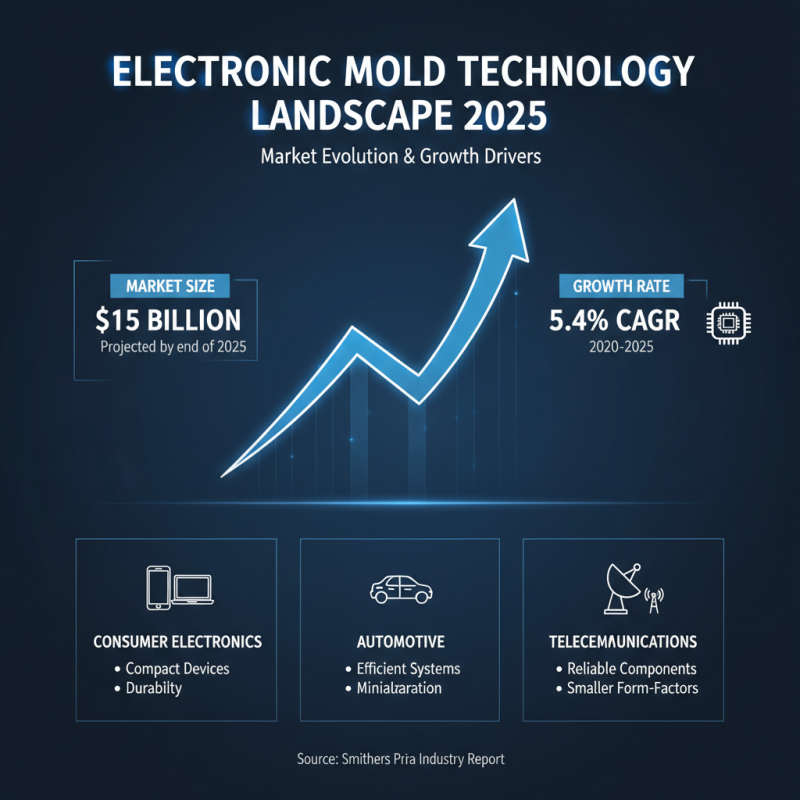

In 2025, the landscape of electronic mold technology has evolved significantly, driven by advancements in materials science and manufacturing processes. According to a recent industry report by Smithers Pira, the electronic molding market is projected to reach $15 billion by the end of the year, reflecting a compound annual growth rate (CAGR) of 5.4% from 2020 to 2025. This growth is fueled by the increasing demand for more efficient and compact electronic devices across sectors such as consumer electronics, automotive, and telecommunications, where durability and miniaturization are paramount.

The integration of smart technologies and automation in the mold-making process has further revolutionized the industry. Companies are adopting Industry 4.0 principles, which leverage IoT and AI to enhance precision and reduce waste during production. A study by McKinsey estimates that smart manufacturing technologies could reduce costs by 20-30% while improving product quality. In addition, the ongoing research in biodegradable materials and sustainable practices is reshaping the market dynamics, with 30% of new mold designs expected to incorporate eco-friendly materials by 2025, addressing both consumer demand and regulatory pressures for sustainability. This transformation illustrates the industry's commitment to innovation while tackling environmental challenges.

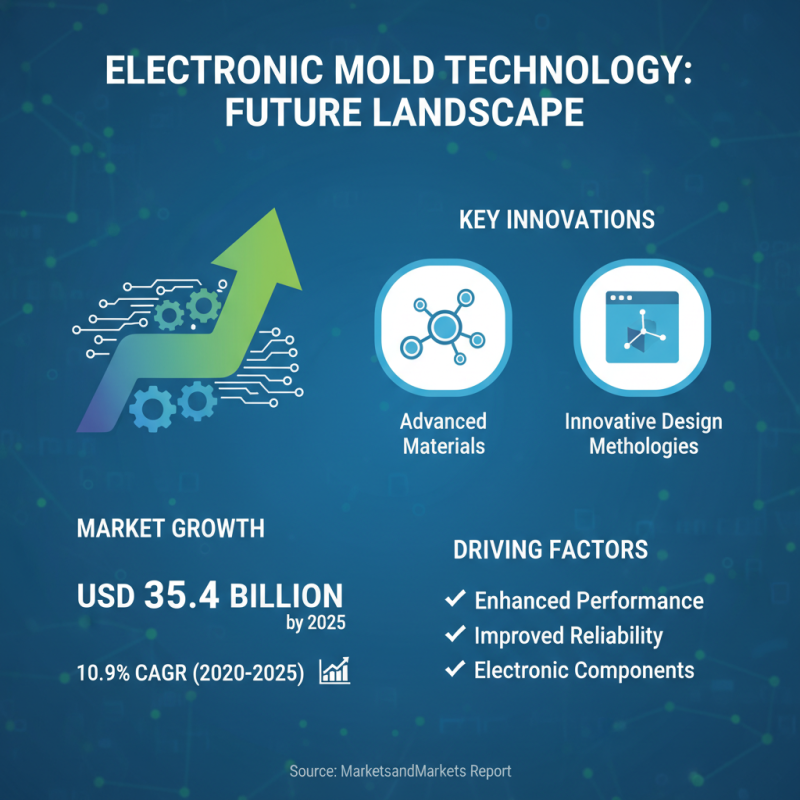

The electronic mold technology landscape is undergoing significant transformation, driven by several key innovations poised to shape its future. According to a recent report by MarketsandMarkets, the global market for electronic molds is projected to reach USD 35.4 billion by 2025, growing at a CAGR of 10.9% from 2020. This robust growth is primarily fueled by advancements in materials and design methodologies that enhance the performance and reliability of electronic components.

One of the notable innovations is the integration of smart manufacturing techniques using artificial intelligence and machine learning. These technologies facilitate predictive maintenance and optimize production processes, significantly reducing downtime and costs. Additionally, the adoption of advanced materials, such as high-performance thermoplastics and composites, allows for greater design flexibility, improved thermal management, and enhanced overall functionality of electronic devices. The deployment of simulation software to create accurate digital twins also contributes to efficient design iterations, allowing engineers to assess the impact of modifications before physical production begins.

Furthermore, sustainability is becoming a crucial aspect of electronic mold design. Eco-friendly practices, such as using recyclable materials and energy-efficient manufacturing processes, are gaining traction. Reports indicate that nearly 60% of manufacturers are now prioritizing sustainability in their product development strategies. This shift not only meets regulatory requirements but also aligns with the increasing demand from consumers for environmentally responsible products, ensuring the longevity of innovations in the electronic mold sector.

The electronic mold manufacturing industry is currently experiencing a significant transformation driven by sustainability trends. According to a report by the International Data Corporation (IDC), nearly 70% of manufacturers are prioritizing sustainability as part of their operational strategy. This shift is largely motivated by increasing consumer demand for eco-friendly products and the need to comply with stringent environmental regulations. As a result, companies are investing in energy-efficient machinery, sustainable materials, and waste reduction practices to minimize their environmental impact throughout the mold production process.

One of the most prominent innovations in this sector is the rise of additive manufacturing techniques, which enable the creation of molds with less material waste compared to traditional subtractive methods. A recent study from the American Society for Testing and Materials (ASTM) noted that 3D printing can reduce material waste by up to 90% in some applications. In addition, using bio-based resins and recyclable materials is becoming increasingly common, as manufacturers seek to reduce their carbon footprints. A report from the Ellen MacArthur Foundation highlighted that transitioning to circular production models could yield about $1 trillion in economic benefits annually by 2025, illustrating a strong business case for sustainability-focused innovations in electronic mold technology.

The electronic mold technology sector is rapidly evolving, with emerging materials playing a crucial role in enhancing performance and sustainability. Innovations in thermoplastics and biodegradable materials are set to transform mold manufacturing processes, ensuring that the electronic components meet the growing demand for lightweight and environmentally friendly products. According to a recent report by Grand View Research, the global demand for electronic mold technology is projected to reach $12 billion by 2025, with a notable shift towards advanced materials that offer better thermal stability and durability.

As electronic devices become increasingly compact and complex, the need for high-precision molds is critical. Emerging materials such as polymer composites and advanced ceramics are not only enhancing the efficiency of the molding processes but also improving the final product quality. A study indicates that using these innovative materials can reduce production waste by up to 30%, significantly lowering the environmental impact of manufacturing operations. Consequently, businesses are exploring the integration of nanotechnology in molds to achieve even greater precision and functionality.

Tips for manufacturers include staying abreast of advancements in composite materials and investing in R&D to explore the limitless potential these materials hold. Additionally, focusing on sustainability in material choices not only meets regulatory standards but also resonates with a growing environmentally conscious consumer base. Collaborating with research institutions can provide insights into the latest trends and materials, ensuring a competitive edge in this fast-evolving landscape.

The landscape of mold production is undergoing a significant transformation driven by advancements in automation and artificial intelligence (AI). These technologies are enhancing production efficiency, reducing lead times, and improving the overall quality of molded products. Automation in mold manufacturing introduces robotics and automated systems that streamline repetitive tasks, allowing for faster cycle times and increased precision. This not only alleviates the burden on human workers but also minimizes the potential for errors, leading to higher consistency in production outputs.

AI plays a pivotal role by enabling predictive maintenance and process optimization in mold production. Through data analysis and machine learning algorithms, AI systems can predict equipment failures before they occur, scheduling maintenance at optimal times to avoid downtime. Moreover, AI enhances the design and configuration process of molds by simulating various production scenarios, allowing manufacturers to identify the most efficient methods before physical production begins. As these technologies continue to evolve, the integration of automation and AI in mold production is set to redefine industry standards, fostering a new era of manufacturing that is more efficient, reliable, and responsive to market demands.

| Trend | Description | Impact on Efficiency | Predicted Adoption Rate (%) |

|---|---|---|---|

| Automation of Design Processes | Implementation of automated software to enhance mold design efficiency. | Reduces design time by up to 40% | 70% |

| AI-Driven Quality Control | Machine learning algorithms to inspect mold quality in real-time. | Improves defect detection by 90% | 60% |

| 3D Printing in Mold Production | Use of 3D printing technology for rapid prototyping of molds. | Cuts lead time by 50% | 75% |

| Smart Mold Monitoring Systems | IoT devices to continuously monitor the performance of molds. | Increases uptime by 30% | 50% |

| Sustainable Materials Innovation | Development of eco-friendly materials for mold manufacturing. | Enhances recyclability by 40% | 65% |